- 30

- Sep

I-Dry type transformer user manual instruciton#Isetshenziswa kanjani isiguquli sohlobo olomile?

PHAMBILI

Siyabonga ngokukhetha isiguquli sohlobo olomile esikhiqizwe inkampani yethu.

Ukhethe umkhiqizo we-transformer wohlobo olomile onomsindo ophansi, ukulahlekelwa okuphansi, umthamo oqinile wokulayisha ngokweqile, amandla aphezulu emishini nokusebenza okuthembekile kukagesi.

Ukuze ukwazi ukusebenzisa lo mkhiqizo ngempumelelo nangokwethembeka, sicela ufake, uhlole futhi unakekele umkhiqizo ngokuya ngokuqukethwe yile Manuwali.

I-CATALOG

Ukubuka konke komkhiqizo

Izimo zokusebenza

Imingcele emikhulu yobuchwepheshe

Incazelo yemodeli

Incazelo yesistimu yomkhiqizo

Ukupakishwa komkhiqizo kanye nokuhamba

Ukuhlolwa nokwamukelwa

Ukuhlola okubonakalayo ngaphambi kokufakwa

Ukuhlolwa kokuhlolwa ngaphambi kokuqalisa ukusebenza

Ukusebenza kwenethiwekhi

Maintenance

Ukuphepha kusemqoka

Ukubuka konke komkhiqizo

Iziguquli zamandla zohlobo lwe-SCB ezifakwe i-resin-insulated dry-type zinezinzuzo zokuphepha, ukwethembeka, ukonga amandla kanye nokugcinwa kalula. Uma kucatshangelwa ukuphepha kwezomnotho nokusebenza kwemvelo, lolu chungechunge lwama-transformer lunamathemba abanzi okusebenza. Ukwakhiwa komkhiqizo kuthuthukile, inqubo iqinile, futhi ukuhlolwa kuphelele. I-high-voltage winding ithatha ama-conductor ekhwalithi ephezulu, kanye nezinto ezinhle kakhulu zokuvikela ezenziwe nge-vacuum casting kanye nokwelapha. I-low-voltage winding ilinyazwe ngezinto ezisezingeni eliphezulu ze-foil, futhi umgogodla wensimbi wenziwe ngeshidi lensimbi ye-silicon esezingeni eliphakeme elivumela ukubanda, elenziwe ngobuchwepheshe obuhle kakhulu. Ngakho-ke, umkhiqizo unamandla amakhulu emishini namandla kagesi, futhi unokusebenza okuhle kakhulu kokushabalalisa ukushisa, umkhiqizo unokukhishwa okuncane okuyingxenye, ukuthembeka okuphezulu, impilo ende yokusebenza, akukho ukumuncwa komswakama, ukunqanda ilangabi, ubufakazi bokuqhuma, akukho ukungcola, ukulahleka okuphansi. , Isisindo esilula, ukulawula izinga lokushisa okuzenzakalelayo kusindisa indawo yokufaka, izindleko zokulungisa, nogesi. Ingangena esikhungweni somthwalo futhi ilungele ukwakhiwa kwamadolobha, izakhiwo eziphakeme kakhulu, izikhungo zentengiso, izindawo zokuhlala, izikhungo zokuzijabulisa nezemidlalo, izibhedlela, izakhiwo zezivakashi, izikhumulo zezindiza, amachweba, iziteshi zesitimela, imigwaqo engaphansi, umhubhe onguthelawayeka izikhungo zokuvikela umoya. , amabhizinisi e-petrochemical, amabhizinisi e-electro-chemical, imboni yokudla, ukuhlanzwa kwendle, amapulatifomu kawoyela aphesheya kwezilwandle, izimayini nezinye izindawo.

2. Izimo zokusebenza

2.1 Ukuphakama kwendawo yokufaka akufanele kudlule ku-1000m, futhi izinga lokushisa le-ambient akufanele libe ngaphezu kuka-40°C (ukwenza ngokwezifiso okukhethekile kungenziwa uma le mfuneko yeqiwa).

2.2 Indawo esetshenziswayo: umswakama ohlobene no-100%, izinga lokushisa le-ambient: +40°C kuya ku-5°C (-5°C ifanele ama-transformer angaphakathi).

2.3 Lo mkhiqizo ngokuvamile uwuhlobo lwasendlini. Indawo yokufaka kufanele ihlanzeke,

ayinalutho lwangaphandle, uthuli, negesi ebolayo, futhi inezimo ezinhle zokungenisa umoya. Uma ifakwe endaweni engaphansi noma kwezinye izindawo ezingenawo umoya ohlanzekile, inkinga yokungena komoya ophoqelelwe kufanele icatshangelwe. Ukulahlekelwa kwalo mkhiqizo nge-IKW ngayinye (Ukulahlekelwa kwe-No-load + ukulahlekelwa komthwalo) mayelana ne-3-4 m3/min yokungena komoya.

2.4 Uma umkhiqizo ufakiwe, ikesi ngokuvamile kufanele libe kude no-800mm

ukusuka odongeni nezinye izithiyo, futhi kufanele kube nebanga lika-300mm

between adjacent transformer casings.

2.5 Ngaphansi kwezimo ezijwayelekile, i-transformer ingafakwa ngqo endaweni yokusetshenziswa, futhi ingafakwa ekusebenzeni ngemva kokufakwa nokuhlolwa. Ezimweni ezine-anti-vibration nezinye izidingo ezikhethekile, isisekelo lapho i-transformer ifakwe khona kufanele ifakwe ngama-bolts, futhi i-transformer kufanele ilungiswe ngama-bolts namantongomane.

3. Imingcele yezobuchwepheshe eyinhloko

3.1 Imvamisa elinganiselwe: 50Hz

3.2 Indlela yokupholisa: AN (AF) noma ngokwezidingo zomsebenzisi

3.3 Ibanga lokuvikela ishell: IP20 noma ngokwezidingo zomsebenzisi.

3.4 Ilebula yeqembu lokuxhuma: Dyn11 noma ngokwezidingo zomsebenzisi.

3.5 Ukulandelana kwesigaba se-Transformer: sibheke ohlangothini lwamandla kagesi aphezulu we-transformer ukusuka kwesokunxele kuya kwesokudla, uhlangothi lwamandla kagesi aphezulu luyi-ABC, kanti uhlangothi lwamandla aphansi luyi-a(o)bc.

3.6 Ikilasi lokufakwa kwamawindi: Ikilasi lika-F noma ngokwezidingo zomsebenzisi.

3.7 Izinga le-insulation

Imvamisa yamandla okumelana ne-voltage yemikhiqizo yebanga elingu-10kV ingu-35kV, kanti i-impulse resistant voltage ingu-75kV. Imvamisa yamandla okumelana nogesi wemikhiqizo yekilasi elingu-20kV ngu-50kV, i-impulse resistant voltage ngu-125kV, kanye nefrikhwensi yamandla okumelana no-voltage wemikhiqizo yeklasi engu-30kV ngu-70kV, kanti i-impulse voltage voltage ingu-170kV.

3.8 Umkhawulo wezinga lokushisa:

Izinga lokushisa lesistimu ye-insulation (C): 155. Isilinganiso esiphezulu sokushisa (k): 100.

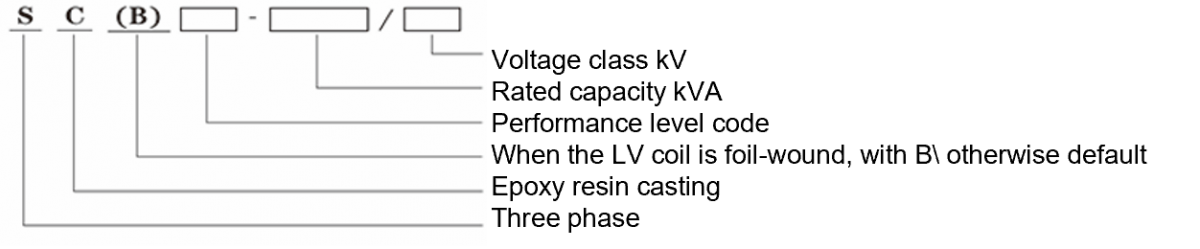

4. Incazelo yemodeli

5. Incazelo yesistimu yomkhiqizo

5.1 Isibonisi sezinga lokushisa kanye nohlelo lokulawula izinga lokushisa

Lo mkhiqizo ungahlonyiswa ngesistimu yokulawula izinga lokushisa ngokwezidingo zomsebenzisi, futhi imisebenzi yawo yile:

(1) Thola izinga lokushisa lekhoyili lapho i-transformer isebenza, bese uyiveza

ngokuzenzakalelayo.

(2) Setha isiphephetha-moya ukuthi siqale, bese uqala ifeni lapho izinga lokushisa ikhoyili lifinyelela ku-80 °C (inani elizenzakalelayo, liyalungiseka).

(3) I-alamu yezinga lokushisa elingaphezulu, lapho izinga lokushisa ikhoyili lifinyelela ku-130 °C (inani elizenzakalelayo, elilungisekayo), kukhishwa isignali ye-alamu.

(4) Uhambo lwezinga lokushisa elingaphezu kwamandla, lapho izinga lokushisa le-ambient lomugqa lidlula

150 °C (inani elizenzakalelayo, liyalungiseka), isignali yohambo iyaphuma.

(5) Lapho umkhawulo obekiwe we-thermometer yesignali weqiwe, ifeni ingaba

iqalile futhi yamiswa, ukunikezwa kwamandla kunganqanyulwa, futhi i-transformer ingavikelwa.

5.2 Uhlelo lokupholisaIndlela yokupholisa ukuzipholisa ngokwakho (AN). Ngesikhathi sokuzipholisa, amandla okukhiphayo angu-100%, futhi ukulayishwa kwesikhathi esifushane kuvunyelwe ngesikhathi sokupholisa ukujikeleza komoya okuphoqelekile (AF).

5.3 Idigri yokuvikelaUma i-transformer ingahlonyiwe ngekesi, izinga lokuvikela lithi IP00 ukuze lisetshenziswe endlini; uma umsebenzisi eyidinga, ingafakwa i-casing, okungukuthi, i-IP20 noma i-IP30 noma i-IP40 (uma izinga lokuvikela i-transformer liphezulu, i-transformer kufanele icatshangelwe ngokuhlehlisa ukusebenza).

Qaphela: Indawo ebiyelwe ye-IP20 ingavimbela ukungena kwezinto eziqinile zangaphandle ezinkulu kuno-12mm futhi inikeze umgoqo wokuphepha wengxenye ebukhoma. Igobolondo elivikelayo le-IP30 lingavimbela ukungena kwezinto zangaphandle ezinkulu kuno-2.5mm. Igobolondo le-1P40 lingavimbela izinto zangaphandle ezinkulu kuno-1mm ukuthi zingangeni.

6. Ukupakishwa komkhiqizo kanye nokuhamba

6.1 Imikhiqizo ihlukaniswe yaba izinhlobo ezimbili: uhlobo oluvulekile (olungenalo ikhava yokuvikela) kanye nohlobo lokuvikela (olunekhava yokuvikela), oluvame ukuthuthwa ngololiwe, umgwaqo wamanzi kanye nothelawayeka. Amaswishi, ama-thermostat, izinto zokupholisa umoya, izinto zokuvikela zangaphandle, njll. zidinga ukupakishwa ngokwehlukana) noma zipakishwe zizonke ukuze zithuthwe. Ama-Cranes, amawintshi noma eminye imishini yokuthutha ehambisanayo ingasetshenziswa ukuphakamisa nokwethula imikhiqizo.

6.2 Ngesikhathi sokuthuthwa komkhiqizo, kufanele kube nezinyathelo ezivimbela imvula ukuvimbela amanzi emvula ukuthi angashoni.

6.3 Enqubweni yokuphakamisa nokuthutha imikhiqizo ngamabhokisi okupakisha, izintambo kufanele zilengiswe ezindaweni zokulala emagumbini amane angaphansi kwebhokisi lokupakisha, futhi imikhiqizo engapakishwanga kufanele iphakanyiswe ngemishini ekhethekile yokuphakamisa, engaphakanyiswa i-100mm. -150mm ukusuka phansi kuqala, bese Ngokusemthethweni Ukuphakamisa.

6.4 Ngesikhathi sokuthutha, akumele kube nemithambeka ekhuphukayo nephansi engaphezu kuka-15° kulayini wokuthutha. Ukuze kuqinisekiswe ukuthi imoto ingakwazi ukuthwala umthwalo ngokulinganayo, isikhungo se-gravity yomkhiqizo kufanele sibekwe kumugqa omaphakathi wemoto ngesikhathi sokulayisha. Ukuze uvimbele

ukugudluzwa kanye nokugingqika komkhiqizo ngesikhathi sokuthutha, isiqondiso se-eksisi ende yomkhiqizo kufanele sihambisane nesiqondiso sokuthutha, futhi umkhiqizo kufanele uboshwe ngokuqinile emotweni yokuthutha.

6.5 Uma ulayisha futhi wethula ngaphandle kwe-crane, izidingo zobuchwepheshe zokuphepha kufanele kuhlangatshezwane nazo, futhi umthamo wokuphakamisa kufanele uhlolwe ukuze kubonakale ukuthi uyahambisana yini nesisindo sokuthutha somkhiqizo.

6.6 For products with a trolley required by the user, a trolley with rollers is installed at the bottom, which is generally unloaded during transportation to ensure the stability of the product transportation. After arriving at the destination, it is reset and installed before installation. Products with a trolley. By changing the direction of the roller shafts at both ends of the frame by 90°,

umkhiqizo ungahanjiswa uvundlile noma uqonde phezulu.

6.7 Ngemva kokuba umkhiqizo ulethiwe endaweni, isikhathi sokupaka endaweni yokuthutha kufanele sifinyezwe ngangokunokwenzeka (gwema ukupaka endaweni evulekile). Ngaphambi kokufakwa, kufanele ipakwe endaweni evaliwe, eyomile futhi engenawo umoya ngangokunokwenzeka. Ngesikhathi esifanayo, kufanele kuthathwe izinyathelo zokwenza umkhiqizo ungantshontshi, ungangenwa umswakama futhi unqande Uthuli, ukungcola, iqhubu, umonakalo kanye nokungcola.

7. Ukuhlolwa nokwamukelwa

7.1 Ngemva kokuthola umkhiqizo, umsebenzisi kufanele avule ibhokisi ukuze lihlolwe futhi lamukelwe kusenesikhathi, ahlole ukuthi izinto ezisohlwini lokupakisha ziphelele yini, ahlole ukuthi i-transformer yonakele yini ngesikhathi sokuthutha, noma izingxenye zomkhiqizo zonakele futhi ziyasuswa, futhi kungakhathaliseki ukuthi ama-fasteners akhululekile, noma ngabe i-insulation yonakalisiwe noma ngabe kukhona iminonjana yokungcola, njll.

7.2 Hlola ukuthi ingabe idatha eku-nameplate yomkhiqizo iyahambisana yini nokucaciswa komkhiqizo, umthamo, ileveli ye-voltage, ilebula yeqembu lokuxhuma, i-short-circuit impedance, njll. eshiwo umsebenzisi.

7.3 Ngemuva kokuthi umkhiqizo usukhululiwe futhi uhloliwe, uma ungasetshenziswanga ngokushesha, kufanele upakishwe kabusha futhi ubekwe endaweni ephephile yasendlini (ukumelana nokweba, ukuvikela umswakama, ukungangeni uthuli, ukunqanda ukungcoliswa, ukungqubuzana) ukuxwayisa ukugcinwa komkhiqizo.

7.4 Ukwamukelwa kwe-transformer kuzosayinwa encwadini ehambisanayo yokunikezelwa kanye nomnyango wezokuthutha. Incwadi yokunikezela izobonisa izinkinga ezitholwe ngesikhathi sokuhlolwa.

7.5 Uma ibhokisi lokupakisha kanye nomkhiqizo kutholakala ukuthi konakele kakhulu ngesikhathi sokuhlolwa, iminyango yezokuthutha neyomshuwalense kufanele yaziswe ngokushesha, futhi indawo kufanele igcinwe ukuze ilahlwe.

8. Ukuhlolwa okubonakalayo ngaphambi kokufakwa

8.1 Ngemva kokuvula ibhokisi, khipha onogada (uma bekhona) ukuze uhlole isimo sangaphandle, unake ngokukhethekile ubuqotho bemishini yekhoyili kanye nenkaba, izinga lokucindezelwa kwendilinga yocingo kanye nomgogodla, kanye nokuqiniswa kwekhoyili. amabhawudi ngaphandle koxhumano.

8.2 Ngemva kokuhlolwa, zonke izinto zokubopha kanye nezingxenye zokuminyanisa zamakhoyili nensimbi kufanele ziqiniswe kabusha ngokulandelana, futhi akukho ukuxegiswa okuvunyelwe.

8.3 Setha kabusha izingxenye ezihlakaziwe ngokuhambisana nezinhlinzeko zezimo zobuchwepheshe zefekthri kanye nemiyalelo efanele yesethi ephelele yezingxenyeKufakwe kumzimba we-transformer.

8.4 For dust and dirt on the product, try to use dry compressed air. In special cases, such as cleaning with a rag, the cloth must be dry, clean and lint-free.

8.5 Uma isikhathi sokugcina siside, kukhona amaconsi amanzi noma ukufingqa okukhulu ebusweni be-transformer, kufanele uthathe ukwelashwa okomile, futhi ikhoyili ingasetshenziswa ngemva kokusebenza kokushisa kwekhoyili kufanelekile.

9. Ukuhlola ukuhlolwa ngaphambi kokuqalisa ukusebenza

9.1 Linganisa ukumelana kwe-DC kwama-windings kagesi aphezulu naphansi (ukuthi idatha iyahambisana yini nedatha enikezwe esitifiketini sokuhlolwa kwefekthri).

9.2 Hlola ukuqina kwensimbi (ucezu oluphansi ngokuvamile lutholakala ekugcineni kwejoka lensimbi elingezansi noma ijoka lensimbi elingaphezulu), hlola ukuthi ingabe isisekelo sithembekile, ukuthi kukhona yini ukunqwabelana kwento yangaphandle, nokuthi ingabe kukhona inqwaba. -iphuzu eliyisisekelo.

9.3 Ukulinganisa Ukumelana Ne-Insulation

| Isigaba se-voltage | I-10kV | I-20kV | I-30kV |

| High voltage coil to low voltage coil | Ω500MΩ | Ω800MΩ | Ω1000MΩ |

| Ikhoyili ye-voltage ephezulu ukuya phansi | Ω500MΩ | Ω800MΩ | Ω1000MΩ |

| Ikhoyili ye-voltage ephansi (0.4V) ukuya phansi | Ω50MΩ | Ω50MΩ | Ω50MΩ |

| Core to ground | Ω5MΩ | Ω5MΩ | Ω5MΩ |

9.4 Uma wenza ifrikhwensi yamandla ukumelana nokuhlolwa kwe-voltage, intambo yokuhlola izinga lokushisa kufanele ikhishwe endaweni ebiyelwe kuyo ukuze kuvinjwe ukuqhekeka kwezingxenye zangaphakathi ze-thermostat, ngisho nokuwohloka kwekhoyili ye-transformer.

9.5 Hlola ukuthi uhlelo lokuvikela lusesimeni esihle yini.

9.6 Isikhundla sokufakwa kwe-transformer kufanele okungenani sibe ngu-800mm kude nodonga nezinye izinto ezithinta izimo zokushisa ukushisa. Ngemuva kokuthi i-transformer isendaweni, ama-bolts aphansi kufanele axhunywe kumjikelezo ojwayelekile wokumisa ukuze kusekelwe okuthembekile.

10. Ukusebenza kwenethiwekhi

10.1 Ngemuva kokuthi idivayisi yokuvikela eyisizayo kanye nesistimu yokuqapha isisekelwe phansi futhi ifaneleka, i-transformer kufanele iqale isebenze ngaphansi kokungalayishi, futhi ngemva kokuvalwa kokushaqeka kathathu, hlola futhi ulungise uhlelo lokuvikela ukudluliselwa.

10.2 Ngemuva kokuthi umkhiqizo usuphumile efekthri, izindawo zompompi zohlangothi lokucindezela okukhulu zixhunywa ngokuya ngendawo yenani elilinganiselwe. Ukulungiswa kwe-voltage kuyadingeka ngesikhathi sokusebenza. Ngokusho kwe-voltage kampompi ekhonjiswe ku-nameplate yomkhiqizo, izigaba ezintathu zilungiswa ngesikhathi esisodwa ekuxhumekeni kompompi okuhambisanayo (uma kungekho ukuvuswa kanye nokulawulwa kwe-voltage), futhi ukunikezwa kwamandla kwe-transformer kuyanqanyulwa.

10.3 I-transformer ithatha i-thermostat yochungechunge lwe-BWDK, futhi isici sokulinganisa izinga lokushisa sishunyekwe ekugcineni kwekhoyili ye-low-voltage, ekwazi ukubona ngokuzenzakalelayo futhi ibonise amazinga okushisa afanele asebenzayo amakhoyili ezigaba ezintathu. Lapho izinga lokushisa ikhoyili lifinyelela izinga lokushisa elimisiwe, ithemometha ingazivulela ngokuzenzakalelayo ifeni, imise isiphephetha-moya, i-alamu, uhambo, nezinga lokushisa elimisiwe lingalungiswa ngumsebenzisi.

I-11. Isondlo

Ngemuva kokuthi i-transformer yohlobo olomile isebenze isikhathi esithile, amandla kufanele anqanyulwe futhi ukuhlolwa okudingekayo okulandelayo kanye nokugcinwa kufanele kwenziwe.

11.1 Hlola amakhoyili, izintambo zokuvala, amatheminali kampompi nezixhumi ezingxenyeni ezihlukahlukene zomonakalo, ukuwohloka, ukuxega, ukuguquguquka kombala, imikhondo yokuphuma nokugqwala. isilinganiso.

11.2 Khipha uthuli ku-transformer. Zonke izingxenye ezingathinteka ngezandla kufanele zesulwe ngendwangu eyomile ehlanzekile, engenantambo, njll., kodwa akufanele kusetshenziswe izinto zokuhlanza eziguquguqukayo. Ezingxenyeni okunzima ukuzisula ngaphakathi kwekhoyili yensimbi, umoya owomile ocindezelwe kufanele usetshenziselwe ukukhipha uthuli.

11.3 I-transformer efakwe isiphephetha-moya kufanele futhi isuse uthuli nenhlabathi yesiphephetha-moya (qaphela ukuthi ingawohloki ama-blade e-fan ngenxa yokulimala) futhi ihlole igrisi ye-fan bear, futhi yengezele noma ishintshe uma kunesidingo.

11.4 Ngemuva kokuthi ukuhlolwa nokugcinwa kuqediwe, ngaphambi kokuba i-transformer iphinde isebenze futhi, kufanele ibhekwe ngokucophelela ukuthi kukhona yini insimbi noma okungeyona into yangaphandle yensimbi eyehlisiwe, eshiywe kukhoyili kanye nensimbi core kanye nezingxenye ezivikelayo.

12. Izindaba zokuphepha

12.1 Ukunikezwa kwamandla kwesilawuli sezinga lokushisa (kanye nefeni) kufanele kutholwe ngesikrini sokushintshwa, hhayi esixhunywe ngokuqondile ku-transformer.

I-12.2 Ngaphambi kokuthi i-transformer isetshenziswe, uhlelo lokumisa phansi lwegumbi le-transformer kufanele luhlolwe.

12.3 Umnyango wendawo ebiyelwe yi-transformer kufanele uvalwe kuyo

qinisekisa ukuphepha kokusetshenziswa kukagesi.

12.4 Kufanele kube nezinyathelo zokuvimbela izilwane ezincane ukuba zingangeni egumbini le-transformer ukugwema izingozi.

I-12.5 Abasebenzi kufanele bagqoke izicathulo zokuvikela uma bengena ekamelweni le-transformer, banake ibanga eliphephile ukusuka engxenyeni ephilayo futhi bangathinti i-transformer.

12.6 If it is found that the noise of the transformer suddenly increases, you should pay attention to observe the load condition of the transformer and the voltage of the power grid, pay attention to the temperature change of the transformer, and contact the relevant personnel for consultation in time.

12.7 I-transformer kufanele ihlolwe futhi igcinwe njalo iminyaka engu-1-2 ukuze kuqinisekiswe ukusebenza okuvamile kwe-transformer.

12.8 Ukufakwa, ukuhlolwa, ukusebenza kanye nokugcinwa kwe-

i-transformer kumele yenziwe ngochwepheshe abaqeqeshiwe.