- 30

- Sep

Uhlobo olomileyo lwesiguquli somsebenzisi instruciton#Isetyenziswa njani isiguquli sodidi olomileyo?

PHAMBILI

Enkosi ngokukhetha isiguquli sodidi olomileyo oluveliswe yinkampani yethu.

Ukhethe imveliso yenguqu eyomileyo enengxolo ephantsi, ilahleko ephantsi, umthamo owomeleleyo wokugcwala, amandla omatshini aphezulu kunye nokusebenza okuthembekileyo kombane.

Ukuze ukwazi ukusebenzisa le mveliso ngokufanelekileyo nangokuthembekileyo, nceda ufake, uhlole kwaye ugcine imveliso ngokwemixholo yale Manuwali.

CATALOG

Ushwankathelo lweemveliso

Iimeko zomsebenzi

Iiparameters eziphambili zobugcisa

Inkcazo yemodeli

Inkcazo yenkqubo yemveliso

Ukupakishwa kwemveliso kunye nokuhamba

Ukuhlolwa kunye nokwamkelwa

Ukuhlolwa okubonakalayo phambi kofakelo

Uvavanyo lokuhlola ngaphambi kokuba luqalise ukusebenza

Umsebenzi womnatha

nokugcinwa

Imiba yezokhuseleko

1. Isishwankathelo semveliso

I-SCB series resin-insulated dry-type transformers zineenzuzo zokhuseleko, ukuthembeka, ukugcinwa kwamandla kunye nokugcinwa lula. Ukuqwalasela ukhuseleko lwezoqoqosho kunye nokusebenza kokusingqongileyo, olu chungechunge lweenguqu lunombono obanzi wokusetyenziswa. Uyilo lwemveliso luhambele phambili, inkqubo ingqongqo, kwaye uvavanyo lugqibelele. Amajiko-moya anevoltage ephezulu amkela ii-conductors ezikumgangatho ophezulu, kunye nemathiriyeli egqwesileyo yokugquma eyenziwe nge-vacuum casting kunye nokunyanga. I-low-voltage winding inxeba nge-foil material ekumgangatho ophezulu, kwaye i-iron core yenziwe nge-high-permeability high-permeability epholileyo ye-silicon sheet yensimbi, eyenziwe ngobuchwepheshe obubalaseleyo. Ke ngoko, imveliso inamandla omatshini aphezulu kunye namandla ombane, kwaye inokusebenza kakuhle kakhulu kokutshabalalisa ubushushu, imveliso inokukhutshwa okuncinci, ukuthembeka okuphezulu, ubomi obude bokusebenza, akukho ukufunxa ukufuma, ukubuyiswa komlilo, ubungqina bokudubula, akukho ngcoliseko, ilahleko ephantsi. , Ubunzima bokukhanya, ulawulo lobushushu oluzenzekelayo lugcina indawo yofakelo, iindleko zokugcinwa, kunye nombane. Inokungena kwiziko lomthwalo kwaye ilungele ukwakhiwa kwedolophu, izakhiwo eziphakamileyo, amaziko orhwebo, iindawo zokuhlala, amaziko olonwabo kunye nezemidlalo, izibhedlele, izakhiwo zabakhenkethi, izikhululo zeenqwelo moya, amazibuko, izikhululo zikaloliwe, iindlela ezingaphantsi, itonela yeendlela zokhuselo lomoya. , amashishini e-petrochemical, amashishini e-electro-chemical, ishishini lokutya, ukucocwa kwamanzi amdaka, amaqonga e-oyile e-offshore, imigodi kunye nezinye iindawo.

2. Iimeko zokusebenza

2.1 Ukuphakama kwendawo yokufakela akufanele kudlule i-1000m, kwaye ukushisa kwe-ambient akufanele kube ngaphezu kwe-40 ° C (ukulungiswa okukhethekileyo kunokwenziwa ukuba le mfuneko idlulile).

2.2 Ukusetyenziswa kwendawo: ukufuma okuhambelana ne-100%, ubushushu be-ambient: +40 ° C ukuya ku -5 ° C (-5 ° C ifanelekile kwiinguqu zangaphakathi).

2.3 Le mveliso ngokuqhelekileyo luhlobo lwangaphakathi. Indawo yokufakela kufuneka icoceke,

ayinazinto zangaphandle, uthuli, kunye negesi edliwayo, kwaye ineemeko ezilungileyo zokungenisa umoya. Ukuba ifakwe kwindawo engaphantsi okanye kwezinye iindawo ezingenayo umoya, ingxaki yokungena umoya onyanzelekileyo kufuneka ithathelwe ingqalelo. Ilahleko yale mveliso nge-IKW (Ayikho ilahleko yomthwalo + ilahleko yomthwalo) malunga ne-3-4 m3 / min yokungenisa umoya.

2.4 Xa imveliso ifakiwe, i-casing kufuneka ngokubanzi ibe yi-800mm kude

ukusuka eludongeni kunye neminye imiqobo, kwaye kufuneka kubekho umgama we-300mm

phakathi kweengxowa zesiguquli ezikufutshane.

2.5 Kwiimeko eziqhelekileyo, i-transformer inokufakwa ngokuthe ngqo kwindawo yokusetyenziswa, kwaye inokufakwa emva kokufakwa kunye nokuhlolwa. Kwiimeko ezine-anti-vibration kunye nezinye iimfuno ezikhethekileyo, isiseko apho i-transformer ifakwe khona kufuneka ifakwe kunye neebholiti, kwaye i-transformer kufuneka ilungiswe ngamabhothi kunye namantongomane.

3. Iimpawu eziphambili zobugcisa

3.1 Umlinganiselo oqhelekileyo: 50Hz

3.2 Indlela yokupholisa: AN (AF) okanye ngokweemfuno zomsebenzisi

3.3 Ibakala lokhuseleko lweShell: IP20 okanye ngokweemfuno zomsebenzisi.

3.4 Ileyibhile yeqela loqhagamshelwano: Dyn11 okanye ngokweemfuno zomsebenzisi.

3.5 Ukulandelelana kwesigaba seTransformer: ejongene necala eliphezulu le-voltage ye-transformer ukusuka kwesobunxele ukuya ngasekunene, i-high-voltage side yi-ABC, kunye ne-low-voltage side yi-a (o) bc.

3.6 Iklasi yokugquma i-insulation: Iklasi F okanye ngokweemfuno zomsebenzisi.

3.7 Inqanaba le-insulation

Amandla ombane okumelana nombane weemveliso zodidi lwe-10kV yi-35kV, kunye ne-impulse resistant voltage yi-75kV. Amandla ombane okumelana nombane weemveliso zeklasi ye-20kV yi-50kV, amandla ombane okumelana ne-impulse yi-125kV, kunye ne-frequency yamandla okumelana nombane weemveliso zeklasi ye-30kV yi-70kV, kunye ne-impulse resistant voltage yi-170kV.

3.8 Umda wokunyuka kobushushu:

Ukushisa kwenkqubo ye-Insulation (C): 155. Ukuphakama okuphezulu kweqondo lokushisa (k): 100.

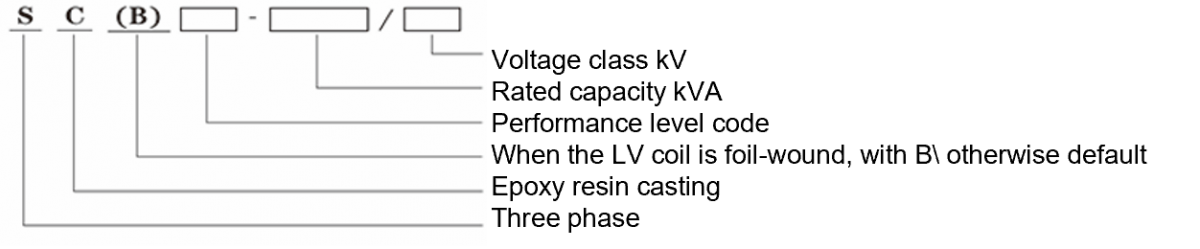

4. Inkcazo yemodeli

5. Inkcazo yenkqubo yemveliso

5.1 Umboniso wobushushu kunye nenkqubo yokulawula ubushushu

Le mveliso inokuxhotyiswa ngenkqubo yokulawula ubushushu bokubonisa ubushushu ngokweemfuno zomsebenzisi, kwaye imisebenzi yayo yile:

(1) Khangela ubushushu bekhoyili xa i-transformer isebenza, kwaye uyibonise

ngokuzenzekelayo.

(2) Misela ifeni ukuba iqalise, kwaye uqalise ifeni xa ubushushu bekhoyili bufikelela kuma-80 °C (ixabiso elimiselweyo, liyalungiseka).

(3) I-alamu yokushisa okungaphezulu, xa ubushushu bekhoyili bufikelela kwi-130 ° C (ixabiso elingagqibekanga, elinokulungiswa), uphawu lwe-alarm lukhutshwa.

(4) Uhambo lobushushu obungaphezulu, xa ubushushu be-ambient bomgca budlula

I-150 °C (ixabiso elihlala lihleli, lilungelelaniswe), uphawu lohambo luyaphuma.

(5) Xa umda omiselweyo wethemometha yomqondiso ugqithisiwe, ifeni ingaba

yaqala kwaye yayeka, unikezelo lwamandla lunokunqunyulwa, kwaye i-transformer inokukhuselwa.

5.2 Inkqubo yokupholisaIndlela yokupholisa kukuzipholisa (AN). Ngethuba lokuzipholisa, umthamo wokukhupha ngu-100%, kwaye ukugqithisa kwexesha elifutshane kuvunyelwe ngexesha lokupholisa umoya wokujikeleza umoya (AF).

5.3 Iqondo lokukhuselaXa i-transformer ingaxhotyiswanga nge-casing, ibakala lokukhusela yi-IP00 yokusetyenziswa kwangaphakathi; ukuba umsebenzisi uyayifuna, inokuxhotyiswa nge-casing, oko kukuthi, i-IP20 okanye i-IP30 okanye i-IP40 (xa ibakala lokukhusela i-transformer liphezulu, i-transformer kufuneka ithathelwe ingqalelo ngokuchithwa komsebenzi).

Qaphela: Indawo ebiyelweyo ye-IP20 inokuthintela ukungena kwezinto eziqinileyo zangaphandle ezinkulu kune-12mm kwaye ibonelele ngomqobo wokhuseleko kwindawo ephilayo. Igobolondo ekhuselayo ye-IP30 inokuthintela ukungena kwezinto zangaphandle ezinkulu kune-2.5mm. Iqokobhe le-1P40 linokuthintela izinto zangaphandle ezinkulu kune-1mm ekungeneni.

6. Ukupakishwa kwemveliso kunye nokuthutha

6.1 Iimveliso zihlulwe zibe zimbini iintlobo: uhlobo oluvulekileyo (ngaphandle kwesikhuselo sokukhusela) kunye nohlobo lokukhusela (kunye nesikhuselo sokukhusela), esihlala sithuthwa ngomzila kaloliwe, umzila wamanzi kunye nomgwaqo omkhulu. Iiswitshi, ii-thermostats, izixhobo zokupholisa umoya, izixhobo zokukhusela zangaphandle, njl.njl. kufuneka zipakishwe ngokwahlukeneyo) okanye zipakishwe xa zizonke ukuze zithuthwe. IiCranes, iiwintshi okanye ezinye iimatshini zothutho ezihambelanayo zingasetyenziselwa ukuphakamisa kunye nokothula iimveliso.

6.2 Ngexesha lokuthuthwa kwemveliso, kufuneka kubekho amanyathelo okuthintela imvula ukukhusela amanzi emvula ukuba angangeni.

6.3 Kwinkqubo yokuphakamisa kunye nokuthutha iimveliso ngeebhokisi zokupakisha, iintambo kufuneka zixhonywe kwiindawo zokulala kwiikona ezine ezisezantsi zebhokisi lokupakisha, kwaye iimveliso ezingabonakaliyo kufuneka ziphakanyiswe ngezixhobo ezikhethekileyo zokuphakamisa, ezinokuphakanyiswa 100mm. -150mm ukusuka emhlabeni kuqala, kwaye emva koko ngokusesikweni Ukuphakamisa.

6.4 Ngexesha lothutho, akufuneki kubekho amathambeka aphezulu naphantsi angaphezu kwe-15 ° kumgca wothutho. Ukuze kuqinisekiswe ukuba isithuthi sinokuthwala umthwalo ngokulinganayo, i-center of gravity yemveliso kufuneka ibekwe kwindawo ethe nkqo yesithuthi ngexesha lokulayisha. Ukuze kuthintelwe

ukufuduka kunye nokuchithwa kwemveliso ngexesha lokuthutha, isalathiso se-axis ende yemveliso kufuneka ihambelane nesikhokelo sokuthutha, kwaye imveliso kufuneka iboshwe ngokuqinileyo kwisithuthi sokuthutha.

6.5 Xa ulayisha kwaye ukhulula ngaphandle kwe-crane, iimfuno zobugcisa bokhuseleko kufuneka zifezekiswe, kwaye umthamo wokuphakamisa kufuneka uhlolwe ukuba uhambelana nobunzima bokuthutha imveliso.

6.6 Kwiimveliso ezinetroli ezifunwa ngumsebenzisi, i-trolley ene-roller ifakwe ezantsi, ngokuqhelekileyo ikhutshwe ngexesha lokuthutha ukuqinisekisa ukuzinza kokuthuthwa kwemveliso. Emva kokufika kwindawo oya kuyo, isetwa ngokutsha kwaye ifakwe phambi kofakelo. Iimveliso ezinetroli. Ngokutshintsha isalathiso se-roller shafts kuzo zombini iziphelo zesakhelo nge-90 °,

imveliso inokuhanjiswa ngokuthe tye okanye ngokuthe nkqo.

6.7 Emva kokuba imveliso isiwe kwindawo ekuyiwa kuyo, ixesha lokupaka kwindawo yothutho kufuneka licuthwe kangangoko (kuphephe ukupakisha okuvulelekileyo). Ngaphambi kokufakela, kufuneka ipakwe kwindawo egqunyiweyo, eyomileyo kunye nengena umoya kangangoko kunokwenzeka. Kwangaxeshanye, amanyathelo kufuneka athatyathwe ukwenza imveliso ichasene nobusela, ingqine ukufuma kunye nokuchasana nothuli, ukungcola, iqhuma, umonakalo kunye nokungcola.

7. Ukuhlolwa nokwamkelwa

7.1 Emva kokufumana imveliso, umsebenzisi kufuneka avule ibhokisi yokuhlola kunye nokwamkelwa ngexesha, khangela ukuba izinto ezidweliswe kuluhlu lokupakisha zigqityiwe, khangela ukuba i-transformer yonakaliswe ngexesha lokuthutha, ingaba iinxalenye zemveliso zonakaliswe kwaye zifuduka, kwaye ingaba i-fasteners ikhululekile, ingaba i-insulation yonakalisiwe kwaye ingaba kukho imikhondo yokungcola, njl.

7.2 Khangela ukuba ingaba idatha ekwinameplate yemveliso iyangqinelana kusini na nenkcazo yemveliso, umthamo, inqanaba lombane, ileyibhile yeqela loqhagamshelo, i-short-circuit impedance, njl. njl. echazwe ngumsebenzisi.

7.3 Emva kokuba imveliso ikhutshwe kwaye ihlolwe, ukuba ayifakwanga ekusebenzeni ngokukhawuleza, kufuneka iphinde ifakwe kwakhona kwaye ibekwe kwindawo ekhuselekileyo yangaphakathi (i-anti-ubusela, i-mswakama-proof, i-dust-proof, i-anti-fouling, i-anti-collision) ukulumkisa ukugcinwa kwemveliso.

7.4 Ukwamkelwa kwe-transformer kuya kusayinwa kwileta ehambelanayo yokunikezelwa kunye nesebe lezothutho. Ileta yokunikezela iya kubonisa iingxaki ezifunyenwe ngexesha lokuhlolwa.

7.5 Ukuba ibhokisi yokupakisha kunye nemveliso ifunyenwe yonakele kakhulu ngexesha lokuhlolwa, amasebe othutho kunye ne-inshurensi kufuneka aziswe ngokukhawuleza, kwaye indawo leyo kufuneka igcinwe ukuze ilahlwe.

8. Ukuhlolwa okubonakalayo phambi kofakelo

8.1 Emva kokuvula ibhokisi, susa abalindi (ukuba kukho) ukujonga imeko yangaphandle, ingqalelo ngokukodwa ukunyaniseka komatshini wekhoyili kunye nombindi, iqondo lokunyanzeliswa kwesangqa socingo kunye nombindi, kunye nokuqiniswa kwe-coil. iibholiti ngaphandle koqhagamshelwano.

8.2 Emva kokuhlolwa, zonke iifasteners kunye ne-compression parts of coils and iron cores kufuneka ziphinde ziqiniswe ngokulandelelana, kwaye akuvumelekanga ukukhulula.

8.3 Setha kwakhona iinxalenye ezichithiweyo ngokuhambelana nemimiselo yeemeko zobugcisa befektri kunye nemiyalelo echaphazelekayo yesethi epheleleyo yamacandelo eFakelwe kwi-transformer body.

8.4 Ngothuli kunye nokungcola kwimveliso, zama ukusebenzisa umoya owomileyo oxinanisiweyo. Kwiimeko ezikhethekileyo, ezifana nokucoca nge-rag, ilaphu kufuneka lome, licoceke kwaye lingabikho.

8.5 Xa ixesha lokugcinwa lide, kukho amaconsi amanzi okanye ukuxinwa okunzulu kumphezulu we-transformer, kufuneka uthathe unyango olomileyo, kwaye i-coil ingasetyenziselwa emva kokusebenza kwe-insulation ye-coil ifanelekile.

9. Uvavanyo lokuhlola phambi kokuba luqalise ukusebenza

9.1 Linganisa ukuxhathisa kwe-DC kumoya wombane ophezulu kunye nophantsi (ukuba ngaba idatha iyahambelana nedatha enikwe kwisiqinisekiso sovavanyo lwasefektri).

9.2 Qwalasela ukusekwa kombindi wentsimbi (iqhekeza lesiseko lihlala ngokuqhelekileyo ekupheleni kwedyokhwe yentsimbi esezantsi okanye idyokhwe yentsimbi ephezulu), khangela ukuba isiseko sithembekile, ukuba kukho izinto zangaphandle ezidityanisiweyo, nokuba kukho izinto ezininzi. -inqaku lesiseko.

9.3 Ukulinganisa ukuNxhathisa kwi-Insulation

| Iklasi yombane | 10kV | 20kV | 30kV |

| Ikhoyili yombane ophezulu ukuya kwikhoyili yombane ophantsi | 500MΩ | 800MΩ | 1000MΩ |

| Ikhoyili yombane ophezulu ukuya emhlabeni | 500MΩ | 800MΩ | 1000MΩ |

| Ikhoyili yombane ophantsi (0.4V) ukuya emhlabeni | 50MΩ | 50MΩ | 50MΩ |

| Undoqo ukuya emhlabeni | 5MΩ | 5MΩ | 5MΩ |

9.4 Xa usenza i-frequency yamandla ukumelana novavanyo lombane, ucingo lokulawula ubushushu kufuneka lukhutshwe kwindawo ebiyelweyo ukuze kuthintelwe ukuqhawuka kwamalungu angaphakathi e-thermostat, kunye nokuqhekeka kwekhoyili ye-transformer.

9.5 Khangela ukuba inkqubo yokhuselo ikwimeko entle na.

9.6 Indawo yokufakela i-transformer kufuneka ibe ubuncinane ubuncinane be-800mm kude nodonga kunye nezinye izinto ezichaphazela iimeko zokutshatyalaliswa kobushushu. Emva kokuba i-transformer isendaweni, iibholiti zokumisa kufuneka zidibaniswe kwisiphaluka esiqhelekileyo somgangatho othembekileyo.

10. Ukusebenza kwenethiwekhi

10.1 Emva kokuba isixhobo sokukhusela esincedisayo kunye nenkqubo yokubeka iliso isekelwe phantsi kwaye ifanelekile, i-transformer kufuneka iqale iqhube phantsi komthwalo, kwaye emva kwezihlandlo ezintathu zokutshatyalaliswa zivaliwe, khangela kwaye ulungelelanise inkqubo yokukhusela i-relay.

10.2 Emva kokuba imveliso ishiya umzi-mveliso, iindawo zompompo zecala loxinzelelo oluphezulu zixhunyiwe ngokwexabiso elilinganisiweyo. Ukulungiswa kwe-voltage kuyadingeka ngexesha lokusebenza. Ngokwe-voltage yempompo eboniswe kwi-nameplate yemveliso, izigaba ezithathu zilungelelaniswa ngaxeshanye kuqhagamshelo lwempompo ehambelanayo (xa kungekho excitation kunye nokulawulwa kombane), kwaye umbane we-transformer unqunyulwe.

10.3 I-transformer ithatha i-thermostat yochungechunge lwe-BWDK, kwaye into yokulinganisa iqondo lokushisa ifakwe kwi-coil ephezulu ye-coil ye-low-voltage, enokuthi ibone ngokuzenzekelayo kwaye ibonise ukushisa okuhambelanayo okusebenzayo kweekhoyili zesigaba sesithathu. Xa ubushushu bekhoyili bufikelela kubushushu obumiselweyo, ithemometha inokuqalisa ngokuzenzekelayo ifeni, iyeke ifeni, ialarm, uhambo, kunye nobushushu obumiselweyo bunokulungiswa ngumsebenzisi.

11. Ulungiso

Emva kokuba i-transformer eyomileyo isebenze ixesha elithile, umbane kufuneka unqunyulwe kwaye uhlolo olulandelayo oluyimfuneko kunye nokugcinwa kufuneka lwenziwe.

11.1 Qwalasela iikhoyili, iingcingo zokutywina, iitheminali zompompo kunye neziqhoboshi kwiindawo ezahlukeneyo zokonakaliswa, ukuguqulwa, ukuxega, ukuguquguquka kwebala, ukukhutshelwa komhlwa kunye nomhlwa. umlinganiselo.

11.2 Susa uthuli kwi-transformer. Zonke iindawo ezinokuphathwa ngezandla kufuneka zosulwe ngelaphu elomileyo elicocekileyo, elingena-lint, njl. Kwiindawo ezinzima ukuzosula ngaphakathi kwikhoyili yentsimbi, umoya owomileyo ocinezelweyo kufuneka usetyenziswe ukuvuthela uthuli.

11.3 I-transformer exhotywe nge-fan kufuneka kwakhona isuse uthuli kunye nomhlaba kwi-fan (qaphela ukuba ungakhubaza ii-blades ze-fan ngenxa yomonakalo) kwaye uhlolisise igrisi ye-fan bearing, kwaye uyifake okanye uyitshintshe xa kuyimfuneko.

11.4 Emva kokuba ukuhlolwa kunye nokugcinwa kugqitywe, ngaphambi kokuba i-transformer iphinde isebenze kwakhona, kufuneka ihlolwe ngokucophelela ukuba kukho nayiphi na into yangaphandle yentsimbi okanye engeyiyo isinyithi, ishiywe kwi-coil kunye nentsimbi yentsimbi kunye nakwiindawo zokukhusela.

12. Imiba yokhuseleko

12.1 Ukunikezelwa kwamandla okulawula ubushushu (kunye nefeni) kufuneka kufunyenwe ngesikrini sokutshintsha, kungekhona ngokuthe ngqo kwi-transformer.

12.2 Ngaphambi kokuba i-transformer isetyenziswe, inkqubo yokumisa igumbi le-transformer kufuneka ihlolwe.

12.3 Ucango lwe-transformer enclosure kufuneka luvalwe

qinisekisa ukhuseleko lokusetyenziswa kombane.

12.4 Kufuneka kubekho amanyathelo okuthintela izilwanyana ezincinci ukuba zingangeni kwigumbi le-transformer ukuphepha iingozi.

12.5 Abasebenzi kufuneka banxibe izicathulo zokukhusela xa bengena kwigumbi le-transformer, banikele ingqalelo kumgama okhuselekileyo ukusuka kwindawo ephilayo kwaye ungathinti i-transformer.

12.6 Ukuba kufunyaniswe ukuba ingxolo ye-transformer iyanda ngokukhawuleza, kufuneka ubeke ingqalelo ukujonga imeko yomthwalo we-transformer kunye ne-voltage yegridi yamandla, ubeke ingqalelo ekutshintsheni kweqondo lokushisa kwi-transformer, kwaye uqhagamshelane nabasebenzi abafanelekileyo ukubonisana ngexesha.

12.7 I-transformer kufuneka ihlolwe kwaye igcinwe rhoqo iminyaka eyi-1-2 ukuqinisekisa ukusebenza okuqhelekileyo kwe-transformer.

12.8 Ufakelo, uvavanyo, ukusebenza kunye nokugcinwa kwe

i-transformer kufuneka yenziwe ngabasebenzi abaqeqeshiweyo.