- 30

- Sep

Mwongozo wa mwongozo wa kibadilishaji cha aina kavu#Jinsi ya kutumia kibadilishaji cha aina kavu?

MBELE

Thank you for choosing the dry-type transformer produced by our company.

You have selected a dry-type transformer product with low noise, low loss, strong overload capacity, high mechanical strength and reliable electrical performance.

In order to enable you to use this product effectively and reliably, please install, inspect and maintain the product according to the contents of this Manual.

Catalogue

Muhtasari wa bidhaa

Hali ya kazi

Kuu ya kiufundi vigezo

Maelezo ya mfano

Product system description

Ufungaji wa bidhaa na usafirishaji

Ukaguzi na kukubalika

Visual inspection before installation

Mtihani wa ukaguzi kabla ya kuanza kufanya kazi

Network operation

Matengenezo

Maswala ya usalama

1. Muhtasari wa bidhaa

SCB mfululizo resin-maboksi kavu-aina ya transfoma nguvu na faida ya usalama, kuegemea, kuokoa nishati na matengenezo rahisi. Kwa kuzingatia usalama wa kiuchumi na matumizi ya mazingira, mfululizo huu wa transfoma una matarajio makubwa ya matumizi. Muundo wa bidhaa ni wa hali ya juu, mchakato ni mkali, na mtihani ni kamili. Vilima vya high-voltage huchukua kondakta za ubora wa juu, na nyenzo bora za kuhami zinazotengenezwa na utupaji wa utupu na uponyaji. Upepo wa voltage ya chini hujeruhiwa na nyenzo za ubora wa juu, na msingi wa chuma umetengenezwa kwa karatasi ya chuma ya silicon ya hali ya juu ya upenyezaji wa hali ya juu, ambayo imetengenezwa kwa teknolojia bora. Kwa hiyo, bidhaa ina nguvu ya juu ya mitambo na nguvu za umeme, na ina utendaji mzuri sana wa kusambaza joto, bidhaa ina kutokwa kwa sehemu ndogo, kuegemea juu, maisha ya muda mrefu ya uendeshaji, hakuna ngozi ya unyevu, retardant ya moto, isiyolipuka, hakuna uchafuzi wa mazingira, hasara ya chini. , Uzito wa mwanga, udhibiti wa joto otomatiki huokoa nafasi ya usakinishaji, gharama za matengenezo, na umeme. Inaweza kupenya ndani ya kituo cha mizigo na inafaa kwa ajili ya ujenzi wa mijini, majengo ya juu, vituo vya biashara, robo za makazi, vituo vya burudani na michezo, hospitali, majengo ya watalii, viwanja vya ndege, bandari, vituo vya reli, subways, njia kuu za ulinzi wa hewa ya raia. , makampuni ya biashara ya petrochemical, makampuni ya biashara ya electro-kemikali, sekta ya chakula, utakaso wa maji taka, majukwaa ya mafuta ya pwani, migodi na maeneo mengine.

2. Masharti ya kufanya kazi

2.1 Urefu wa tovuti ya ufungaji haipaswi kuzidi 1000m, na joto la kawaida haipaswi kuwa zaidi ya 40 ° C (ubinafsishaji maalum unaweza kufanywa ikiwa mahitaji haya yamezidi).

2.2 Mazingira ya matumizi: unyevu wa jamaa 100%, joto la kawaida: +40 ° C hadi -5 ° C (-5 ° C inafaa kwa transfoma ya ndani).

2.3 This product is generally an indoor type. The installation site should be clean,

isiyo na vitu vya kigeni, vumbi, na gesi babuzi, na ina hali nzuri ya uingizaji hewa. Ikiwa imewekwa kwenye basement au maeneo mengine yenye uingizaji hewa mbaya, tatizo la uingizaji hewa wa kulazimishwa linapaswa kuzingatiwa. Upotevu wa bidhaa hii kwa IKW ( Hakuna hasara ya mzigo + kupoteza mzigo) kuhusu 3-4 m3 / min ya uingizaji hewa.

2.4 Wakati bidhaa imesakinishwa, casing kwa ujumla inapaswa kuwa 800mm mbali

kutoka kwa ukuta na vikwazo vingine, na kuwe na umbali wa 300mm

kati ya casings karibu ya transformer.

2.5 Katika hali ya kawaida, transformer inaweza kuwekwa moja kwa moja kwenye tovuti ya matumizi, na inaweza kuweka katika kazi baada ya ufungaji na ukaguzi. Kwa hali ya kupambana na vibration na mahitaji mengine maalum, msingi ambao transformer imewekwa inapaswa kuingizwa na bolts, na transformer inapaswa kudumu na bolts na karanga.

3. Vigezo kuu vya kiufundi

3.1 Rated frequency: 50Hz

3.2 Mbinu ya kupoeza: AN (AF) au kulingana na mahitaji ya mtumiaji

3.3 Shell protection grade: IP20 or according to user requirements.

3.4 Lebo ya kikundi cha muunganisho: Dyn11 au kulingana na mahitaji ya mtumiaji.

3.5 Transformer phase sequence: facing the high-voltage side of the transformer from left to right, the high-voltage side is ABC, and the low-voltage side is a(o)bc.

3.6 Darasa la insulation ya vilima: Darasa la F au kulingana na mahitaji ya mtumiaji.

3.7 Kiwango cha insulation

The power frequency withstand voltage of 10kV grade products is 35kV, and the impulse withstand voltage is 75kV. The power frequency withstand voltage of 20kV class products is 50kV, the impulse withstand voltage is 125kV, and the power frequency withstand voltage of 30kV class products is 70kV, and the impulse withstand voltage is 170kV.

3.8 Kikomo cha ongezeko la joto:

Insulation system temperature (C): 155. Maximum temperature rise (k): 100.

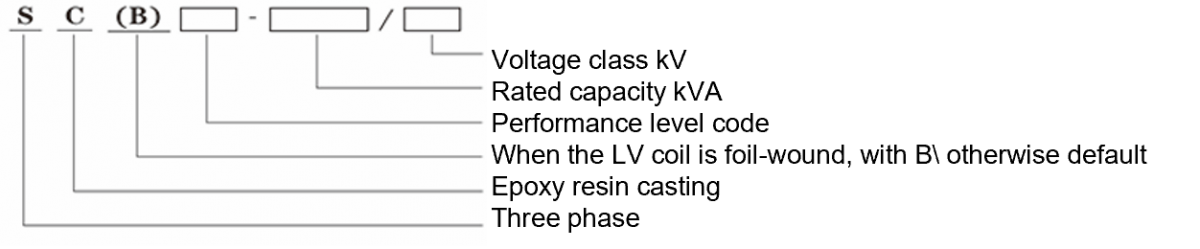

4. Maelezo ya mfano

5. Product system description

5.1 Temperature display and temperature control system

This product can be equipped with a temperature display temperature control system according to the user’s requirements, and its functions are:

(1) Detect the coil temperature when the transformer is running, and display it

moja kwa moja.

(2) Weka feni ili kuwasha, na uwashe feni halijoto ya coil inapofikia 80 °C (thamani chaguo-msingi, inayoweza kurekebishwa).

(3) Kengele ya joto kupita kiasi, halijoto ya coil inapofikia 130 °C (thamani chaguo-msingi, inayoweza kubadilishwa), ishara ya kengele hutolewa.

(4) Safari ya joto kupita kiasi, wakati halijoto iliyoko ya laini inapozidi

150 °C (thamani chaguo-msingi, inayoweza kubadilishwa), mawimbi ya safari hutolewa.

(5) When the set limit of the signal thermometer is exceeded, the fan can be

ilianza na kusimamishwa, ugavi wa umeme unaweza kukatwa, na transformer inaweza kulindwa.

5.2 Mfumo wa kupoezaNjia ya kupoeza ni ya kujipoza yenyewe (AN). Wakati wa kujitegemea baridi, uwezo wa pato ni 100%, na overload ya muda mfupi inaruhusiwa wakati wa baridi ya mzunguko wa hewa ya kulazimishwa (AF).

5.3 Kiwango cha ulinziWakati transfoma haina vifaa vya casing, daraja la ulinzi ni IP00 kwa matumizi ya ndani; ikiwa mtumiaji anaihitaji, inaweza kuwa na vifaa vya casing, yaani, IP20 au IP30 au IP40 (wakati daraja la ulinzi wa transformer ni kubwa, transformer inapaswa kuzingatiwa kwa uendeshaji wa kupungua).

Note: The IP20 enclosure can prevent the entry of solid foreign objects larger than 12mm and provide a safety barrier for the live part. The protective shell of IP30 can prevent the entry of foreign objects larger than 2.5mm. 1P40 shell can prevent foreign objects larger than 1mm from entering.

6. Product packaging and transportation

6.1 Bidhaa zimegawanywa katika aina mbili: aina ya wazi (bila kifuniko cha kinga) na aina ya kinga (yenye kifuniko cha kinga), ambayo kawaida husafirishwa na reli, barabara ya maji na barabara kuu. Swichi, vidhibiti vya halijoto, vifaa vya kupoeza hewa, vifaa vya ulinzi vya nje, n.k. vinahitaji kuunganishwa kando) au kupakizwa kwa ujumla kwa ajili ya usafirishaji. Korongo, winchi au mashine zingine zinazolingana za usafirishaji zinaweza kutumika kuinua na kupakua bidhaa.

6.2 During the transportation of the product, there must be rainproof measures to prevent rainwater from drenching.

6.3 Katika mchakato wa kuinua na kusafirisha bidhaa na masanduku ya ufungaji, kamba zinapaswa kunyongwa kwenye walala kwenye pembe nne za chini ya sanduku la ufungaji, na bidhaa ambazo hazijafungwa zinapaswa kuinuliwa kwa vifaa maalum vya kuinua, ambavyo vinaweza kuinuliwa 100mm. -150mm kutoka ardhini kwanza, na kisha rasmi Kuinua.

6.4 During transportation, there should be no up and down slopes greater than 15° on the transportation line. In order to ensure that the vehicle can bear the load evenly, the center of gravity of the product should be located on the vertical centerline of the vehicle during loading. In order to prevent

kuhamishwa na kupinduliwa kwa bidhaa wakati wa usafirishaji, mwelekeo wa mhimili mrefu wa bidhaa unapaswa kuwa sawa na mwelekeo wa usafirishaji, na bidhaa inapaswa kufungwa kwa uthabiti kwenye gari la usafirishaji.

6.5 Wakati wa kupakia na kupakua bila crane, mahitaji ya kiufundi ya usalama yanapaswa kufikiwa, na uwezo wa kuinua unapaswa kuchunguzwa ili kuona ikiwa inafanana na uzito wa usafiri wa bidhaa.

6.6 For products with a trolley required by the user, a trolley with rollers is installed at the bottom, which is generally unloaded during transportation to ensure the stability of the product transportation. After arriving at the destination, it is reset and installed before installation. Products with a trolley. By changing the direction of the roller shafts at both ends of the frame by 90°,

bidhaa inaweza kuhamishwa kwa usawa au kwa wima.

6.7 After the product is delivered to the destination, the parking time in the transportation state should be shortened as much as possible (avoid open-air parking). Before installation, it should be parked in a covered, dry and ventilated place as much as possible. At the same time, measures should be taken to make the product anti-theft, moisture-proof and anti- Dust, dirt, bump, damage and dirt.

7. Inspection and acceptance

7.1 After receiving the product, the user should open the box for inspection and acceptance in time, check whether the items listed in the packing list are complete, check whether the transformer is damaged during transportation, whether the product parts are damaged and displaced, and whether the fasteners are loose, whether the insulation is damaged and whether there are traces of contamination, etc.

7.2 Check whether the data on the product nameplate is consistent with the product specification, capacity, voltage level, connection group label, short- circuit impedance, etc. specified by the user.

7.3 After the product is unpacked and checked, if it is not put into operation immediately, it should be repackaged and placed in a safe indoor place (anti- theft, moisture-proof, dust-proof, anti-fouling, anti-collision) to warn the storage of the product.

7.4 The acceptance of the transformer shall be signed on the corresponding handover letter together with the transportation department. The handover letter shall reflect the problems found during the inspection.

7.5 Ikiwa sanduku la kufunga na bidhaa zinapatikana kuwa zimeharibiwa sana wakati wa ukaguzi, idara za usafiri na bima zinapaswa kujulishwa mara moja, na tovuti inapaswa kuwekwa kwa ajili ya kuondolewa.

8. Ukaguzi wa Visual kabla ya ufungaji

8.1 Baada ya kufungua sanduku, ondoa walinzi (ikiwa wapo) ili kuangalia hali ya nje, ukizingatia hasa uadilifu wa mitambo ya coil na msingi, kiwango cha kukandamiza kwa mzunguko wa waya na msingi, na kukazwa kwa waya. bolts nje ya muunganisho.

8.2 Baada ya ukaguzi, vifungo vyote na sehemu za ukandamizaji wa coils na cores za chuma lazima zimefungwa tena kwa mlolongo, na hakuna kulegea kunaruhusiwa.

8.3 Reset the dismantled parts in accordance with the provisions of the factory technical conditions and the relevant instructions of the complete set of componentsInstalled on the transformer body.

8.4 For dust and dirt on the product, try to use dry compressed air. In special cases, such as cleaning with a rag, the cloth must be dry, clean and lint-free.

8.5 Wakati muda wa kuhifadhi ni mrefu, kuna matone ya maji au condensation kubwa juu ya uso wa transformer, unapaswa kuchukua matibabu kavu, na coil inaweza kutumika baada ya utendaji insulation ya coil ni sifa.

9. Inspection test before putting into operation

9.1 Measure the DC resistance of the high and low voltage windings (whether the data is consistent with the data given in the factory test certificate).

9.2 Check the grounding of the iron core (the grounding piece is generally located at the end of the lower iron yoke or the upper iron yoke), check whether the grounding is reliable, whether there is foreign matter overlap, and whether there is a multi-point grounding phenomenon.

9.3 Measuring Insulation Resistance

| Voltage class | 10kV | 20kV | 30kV |

| Coil ya juu ya voltage hadi coil ya chini ya voltage | Ω500MΩ | Ω800MΩ | Ω1000MΩ |

| Coil ya juu ya voltage hadi ardhini | Ω500MΩ | Ω800MΩ | Ω1000MΩ |

| Coil ya voltage ya chini (0.4V) hadi chini | Ω50MΩ | Ω50MΩ | Ω50MΩ |

| Core to ground | Ω5MΩ | Ω5MΩ | Ω5MΩ |

9.4 When doing the power frequency withstand voltage test, the temperature control probe wire should be taken out from the wire enclosure to prevent the breakdown of the internal components of the thermostat, and even the breakdown of the transformer coil.

9.5 Check whether the protection system is in good condition.

9.6 Msimamo wa ufungaji wa transformer inapaswa kuwa angalau 800mm mbali na ukuta na vitu vingine vinavyoathiri hali ya uharibifu wa joto. Baada ya transformer iko, vifungo vya kutuliza vinapaswa kushikamana na mzunguko wa jumla wa kutuliza kwa msingi wa kuaminika.

10. Uendeshaji wa mtandao

10.1 Baada ya kifaa cha ulinzi wa msaidizi na mfumo wa ufuatiliaji ni msingi na wenye sifa, transformer inapaswa kwanza kukimbia bila mzigo, na baada ya mara tatu ya mshtuko kufungwa, angalia na urekebishe mfumo wa ulinzi wa relay.

10.2 Baada ya bidhaa kuondoka kwenye kiwanda, nafasi za bomba za upande wa shinikizo la juu huunganishwa kulingana na nafasi ya thamani iliyokadiriwa. Marekebisho ya voltage inahitajika wakati wa operesheni. Kwa mujibu wa voltage ya bomba iliyoonyeshwa kwenye nameplate ya bidhaa, awamu tatu zinarekebishwa wakati huo huo kwenye uunganisho wa bomba unaofanana (wakati hakuna msisimko na udhibiti wa voltage), na ugavi wa umeme wa transformer hukatwa.

10.3 The transformer adopts the BWDK series thermostat, and the temperature measuring element is embedded in the upper end of the low-voltage coil, which can automatically detect and display the respective working temperatures of the three-phase coils. When the coil temperature reaches the set temperature, the thermometer can automatically start the fan, stop the fan, alarm, trip, and the set temperature can be adjusted by the user.

11. Matengenezo

Baada ya kibadilishaji cha aina kavu kwa muda mrefu, nguvu inapaswa kukatwa na ukaguzi na matengenezo muhimu yafuatayo yanapaswa kufanywa.

11.1 Check coils, sealing wires, tap terminals and fasteners in various parts for damage, deformation, loosening, discoloration, discharge traces and corrosion. measure.

11.2 Remove dust from the transformer. All parts that can be touched by hands should be wiped with a clean, lint-free dry cloth, etc., but no volatile cleaners should be used. For the hard-to-wipe parts inside the iron core coil, dry compressed air should be used to blow off the dust.

11.3 The transformer equipped with the fan should also remove the dust and soil in the fan (be careful not to deform the blades of the fan due to damage) and check the grease of the fan bearing, and supplement or replace it if necessary.

11.4 Baada ya ukaguzi na matengenezo kukamilika, kabla ya transfoma kuanza kufanya kazi tena, inapaswa kuangaliwa kwa uangalifu ikiwa kuna chuma chochote cha kigeni cha chuma au kisicho na metali kimeshuka, kilichoachwa kwenye msingi wa coil na chuma na kwenye sehemu za kuhami joto.

12. Mambo ya usalama

12.1 Ugavi wa nguvu wa mtawala wa joto (na shabiki) unapaswa kupatikana kupitia skrini ya kubadili, sio kushikamana moja kwa moja na transformer.

12.2 Kabla ya kuweka transformer katika kazi, mfumo wa kutuliza wa chumba cha transformer lazima uangaliwe.

12.3 The door of the transformer enclosure should be closed to

kuhakikisha usalama wa matumizi ya umeme.

12.4 There should be measures to prevent small animals from entering the transformer room to avoid accidents.

12.5 Wafanyakazi wanapaswa kuvaa viatu vya kuhami wakati wa kuingia kwenye chumba cha transformer, makini na umbali salama kutoka sehemu ya kuishi na usigusa transformer.

12.6 Ikiwa itagunduliwa kuwa kelele ya kibadilishaji huongezeka ghafla, unapaswa kuzingatia kuangalia hali ya mzigo wa kibadilishaji na voltage ya gridi ya nguvu, makini na mabadiliko ya joto ya kibadilishaji, na wasiliana na wafanyikazi wanaohusika. mashauriano kwa wakati.

12.7 Transformer inapaswa kuchunguzwa na kudumishwa mara kwa mara kwa miaka 1-2 ili kuhakikisha uendeshaji wa kawaida wa transformer.

12.8 The installation, testing, operation and maintenance of the

transformer must be undertaken by qualified professionals.