- 30

- Sep

Dry type transformer user manual instruciton#How to use dry-type transformer?

FOREWARD

Thank you for choosing the dry-type transformer produced by our company.

You have selected a dry-type transformer product with low noise, low loss, strong overload capacity, high mechanical strength and reliable electrical performance.

In order to enable you to use this product effectively and reliably, please install, inspect and maintain the product according to the contents of this Manual.

CATALOGUE

Product overview

Working conditions

Main technical parameters

Model description

Product system description

Product packaging and transportation

Inspection and acceptance

Visual inspection before installation

Inspection test before putting into operation

Network operation

Maintenance

Safety matters

1. Product overview

SCB series resin-insulated dry-type power transformers have the advantages of safety, reliability, energy saving and easy maintenance. Considering economical safety and environmental applicability, this series of transformers have wide application prospects. The product design is advanced, the process is strict, and the test is perfect. The high-voltage winding adopts high-quality conductors,and excellent insulating material made by vacuum casting and curing. The low-voltage winding is wound with high-quality foil material, and the iron core is made of high- quality high-permeability cold-rolled silicon steel sheet, which is made with excellent technology. Therefore, the product has high mechanical strength and electrical strength, and has very good heat dissipation performance, the product has small partial discharge, high reliability, long operating life, no moisture absorption, flame retardant, explosion-proof, no pollution, low loss, Light weight, automatic temperature control saves installation space, maintenance costs, and electricity. It can penetrate into the load center and is suitable for urban construction, high-rise buildings, commercial centers, residential quarters, entertainment and sports centers, hospitals, tourist buildings, airports, ports, railway stations, subways, highway tunnel civil air defense facilities, petrochemical enterprises, electro-chemical enterprises, food industry, sewage purification, offshore oil platforms, mines and other places.

2. Working conditions

2.1 The altitude of the installation site should not exceed 1000m, and the ambient temperature should not be higher than 40°C (special customization can be made if this requirement is exceeded).

2.2 Use environment: relative humidity 100%, ambient temperature: +40°C to -5°C (-5°C is suitable for indoor transformers).

2.3 This product is generally an indoor type. The installation site should be clean,

free of foreign matter, dust, and corrosive gas, and has good ventilation conditions. If it is installed in a basement or other poorly ventilated places, the problem of forced ventilation should be considered. The loss of this product per IKW ( No-load loss + load loss) about 3-4 m3/min of ventilation.

2.4 When the product is installed, the casing should generally be 800mm away

from the wall and other obstacles, and there should be a distance of 300mm

between adjacent transformer casings.

2.5 Under normal circumstances, the transformer can be directly placed on the site of use, and can be put into operation after installation and inspection. For situations with anti-vibration and other special requirements, the foundation on which the transformer is installed should be embedded with bolts, and the transformer should be fixed by bolts and nuts.

3. Main technical parameters

3.1 Rated frequency: 50Hz

3.2 Cooling method: AN (AF) or according to user requirements

3.3 Shell protection grade: IP20 or according to user requirements.

3.4 Connection group label: Dyn11 or according to user requirements.

3.5 Transformer phase sequence: facing the high-voltage side of the transformer from left to right, the high-voltage side is ABC, and the low-voltage side is a(o)bc.

3.6 Winding insulation class: F class or according to user requirements.

3.7 Insulation level

The power frequency withstand voltage of 10kV grade products is 35kV, and the impulse withstand voltage is 75kV. The power frequency withstand voltage of 20kV class products is 50kV, the impulse withstand voltage is 125kV, and the power frequency withstand voltage of 30kV class products is 70kV, and the impulse withstand voltage is 170kV.

3.8 Temperature rise limit:

Insulation system temperature (C): 155. Maximum temperature rise (k): 100.

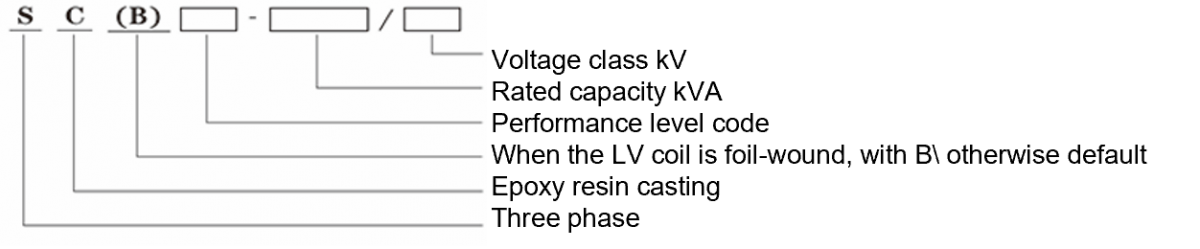

4. Model description

5. Product system description

5.1 Temperature display and temperature control system

This product can be equipped with a temperature display temperature control system according to the user’s requirements, and its functions are:

(1) Detect the coil temperature when the transformer is running, and display it

automatically.

(2) Set the fan to start, and start the fan when the coil temperature reaches 80 °C (default value, adjustable).

(3) Over-temperature alarm, when the coil temperature reaches 130 °C (default value, adjustable), an alarm signal is issued.

(4) Over-temperature trip, when the ambient temperature of the line exceeds

150 °C (default value, adjustable), the trip signal is output.

(5) When the set limit of the signal thermometer is exceeded, the fan can be

started and stopped, the power supply can be cut off, and the transformer can be protected.

5.2 Cooling systemThe cooling method is self-cooling (AN). During self-cooling, the output capacity is 100%, and short-time overload is allowed during forced air circulation cooling (AF).

5.3 Degree of protectionWhen the transformer is not equipped with a casing, the protection grade is IP00 for indoor use; if the user needs it, it can be equipped with a casing, that is, IP20 or IP30 or IP40 (when the transformer protection grade is high, the transformer should be considered for derating operation).

Note: The IP20 enclosure can prevent the entry of solid foreign objects larger than 12mm and provide a safety barrier for the live part. The protective shell of IP30 can prevent the entry of foreign objects larger than 2.5mm. 1P40 shell can prevent foreign objects larger than 1mm from entering.

6. Product packaging and transportation

6.1 The products are divided into two types: open type (without protective cover) and protective type (with protective cover), which are usually transported by railway, waterway and highway. Switches, thermostats, air- cooling devices, external protective devices, etc. need to be packaged separately) or packaged as a whole for transportation. Cranes, winches or other corresponding transportation machinery can be used to lift and unload the products.

6.2 During the transportation of the product, there must be rainproof measures to prevent rainwater from drenching.

6.3 In the process of lifting and transporting products with packaging boxes, the ropes should be hung on the sleepers at the four corners of the bottom of the packaging box, and the unpackaged products should be lifted with special lifting devices, which can be lifted 100mm-150mm from the ground first, and then formally Lifting.

6.4 During transportation, there should be no up and down slopes greater than 15° on the transportation line. In order to ensure that the vehicle can bear the load evenly, the center of gravity of the product should be located on the vertical centerline of the vehicle during loading. In order to prevent

displacement and overturning of the product during transportation, the direction of the long axis of the product should be consistent with the transportation direction, and the product should be firmly bound on the transport vehicle.

6.5 When loading and unloading without a crane, the safety technical requirements should be met, and the lifting capacity should be checked to see if it matches the transport weight of the product.

6.6 For products with a trolley required by the user, a trolley with rollers is installed at the bottom, which is generally unloaded during transportation to ensure the stability of the product transportation. After arriving at the destination, it is reset and installed before installation. Products with a trolley. By changing the direction of the roller shafts at both ends of the frame by 90°,

the product can be moved horizontally or vertically.

6.7 After the product is delivered to the destination, the parking time in the transportation state should be shortened as much as possible (avoid open-air parking). Before installation, it should be parked in a covered, dry and ventilated place as much as possible. At the same time, measures should be taken to make the product anti-theft, moisture-proof and anti- Dust, dirt, bump, damage and dirt.

7. Inspection and acceptance

7.1 After receiving the product, the user should open the box for inspection and acceptance in time, check whether the items listed in the packing list are complete, check whether the transformer is damaged during transportation, whether the product parts are damaged and displaced, and whether the fasteners are loose, whether the insulation is damaged and whether there are traces of contamination, etc.

7.2 Check whether the data on the product nameplate is consistent with the product specification, capacity, voltage level, connection group label, short- circuit impedance, etc. specified by the user.

7.3 After the product is unpacked and checked, if it is not put into operation immediately, it should be repackaged and placed in a safe indoor place (anti- theft, moisture-proof, dust-proof, anti-fouling, anti-collision) to warn the storage of the product.

7.4 The acceptance of the transformer shall be signed on the corresponding handover letter together with the transportation department. The handover letter shall reflect the problems found during the inspection.

7.5 If the packing box and product are found to be seriously damaged during the inspection, the transportation and insurance departments should be notified immediately, and the site should be kept for disposal.

8. Visual inspection before installation

8.1 After opening the box, remove the guards (if any) to check the external condition, paying particular attention to the mechanical integrity of the coil and the core, the degree of compression of the wire circle and the core, and the tightening of the bolts outside the connection.

8.2 After inspection, all fasteners and the compression parts of coils and iron cores must be re-tightened in sequence, and no loosening is allowed.

8.3 Reset the dismantled parts in accordance with the provisions of the factory technical conditions and the relevant instructions of the complete set of componentsInstalled on the transformer body.

8.4 For dust and dirt on the product, try to use dry compressed air. In special cases, such as cleaning with a rag, the cloth must be dry, clean and lint-free.

8.5 When the storage time is long, there are water droplets or serious condensation on the surface of the transformer, you should take dry treatment, and the coil can be used after the insulation performance of the coil is qualified.

9. Inspection test before putting into operation

9.1 Measure the DC resistance of the high and low voltage windings (whether the data is consistent with the data given in the factory test certificate).

9.2 Check the grounding of the iron core (the grounding piece is generally located at the end of the lower iron yoke or the upper iron yoke), check whether the grounding is reliable, whether there is foreign matter overlap, and whether there is a multi-point grounding phenomenon.

9.3 Measuring Insulation Resistance

| Voltage class | 10kV | 20kV | 30kV |

| High voltage coil to low voltage coil | ≥500MΩ | ≥800MΩ | ≥1000MΩ |

| High voltage coil to ground | ≥500MΩ | ≥800MΩ | ≥1000MΩ |

| Low voltage coil (0.4V) to ground | ≥50MΩ | ≥50MΩ | ≥50MΩ |

| Core to ground | ≥5MΩ | ≥5MΩ | ≥5MΩ |

9.4 When doing the power frequency withstand voltage test, the temperature control probe wire should be taken out from the wire enclosure to prevent the breakdown of the internal components of the thermostat, and even the breakdown of the transformer coil.

9.5 Check whether the protection system is in good condition.

9.6 The installation position of the transformer should be at least 800mm away from the wall and other objects that affect the heat dissipation conditions. After the transformer is in place, the grounding bolts should be connected to the general grounding circuit for reliable grounding.

10. Network operation

10.1 After the auxiliary protection device and monitoring system are grounded and qualified, the transformer should first run under no-load, and after three times of shocks are closed, check and adjust the relay protection system.

10.2 After the product leaves the factory, the tap positions of the high pressure side are connected according to the rated value position. Voltage adjustment is required during operation. According to the tap voltage indicated on the product nameplate, three phases are simultaneously adjusted on the corresponding tap connection (when there is no excitation and voltage regulation), and the power supply of the transformer is cut off.

10.3 The transformer adopts the BWDK series thermostat, and the temperature measuring element is embedded in the upper end of the low-voltage coil, which can automatically detect and display the respective working temperatures of the three-phase coils. When the coil temperature reaches the set temperature, the thermometer can automatically start the fan, stop the fan, alarm, trip, and the set temperature can be adjusted by the user.

11. Maintenance

After the dry-type transformer has been running for a period of time, the power should be cut off and the following necessary inspections and maintenance should be carried out.

11.1 Check coils, sealing wires, tap terminals and fasteners in various parts for damage, deformation, loosening, discoloration, discharge traces and corrosion. measure.

11.2 Remove dust from the transformer. All parts that can be touched by hands should be wiped with a clean, lint-free dry cloth, etc., but no volatile cleaners should be used. For the hard-to-wipe parts inside the iron core coil, dry compressed air should be used to blow off the dust.

11.3 The transformer equipped with the fan should also remove the dust and soil in the fan (be careful not to deform the blades of the fan due to damage) and check the grease of the fan bearing, and supplement or replace it if necessary.

11.4 After the inspection and maintenance are completed, before the transformer is put into operation again, it should be carefully checked whether there is any metal or non-metallic foreign matter dropped, left in the coil and iron core and on the insulating parts.

12. Safety matters

12.1 The power supply of the temperature controller (and the fan) should be obtained through the switch screen, not directly connected to the transformer.

12.2 Before the transformer is put into operation, the grounding system of the transformer room must be checked.

12.3 The door of the transformer enclosure should be closed to

ensure the safety of electricity use.

12.4 There should be measures to prevent small animals from entering the transformer room to avoid accidents.

12.5 The staff must wear insulating shoes when entering the transformer room, pay attention to the safe distance from the live part and do not touch the transformer.

12.6 If it is found that the noise of the transformer suddenly increases, you should pay attention to observe the load condition of the transformer and the voltage of the power grid, pay attention to the temperature change of the transformer, and contact the relevant personnel for consultation in time.

12.7 The transformer should be inspected and maintained regularly for 1-2 years to ensure the normal operation of the transformer.

12.8 The installation, testing, operation and maintenance of the

transformer must be undertaken by qualified professionals.