- 30

- Sep

Quruq turdagi transformator foydalanuvchi qo’llanmasi # Quruq turdagi transformatordan qanday foydalanish kerak?

Oldindan

Kompaniyamiz tomonidan ishlab chiqarilgan quruq turdagi transformatorni tanlaganingiz uchun tashakkur.

Siz past shovqin, kam yo’qotish, kuchli ortiqcha yuk ko’tarish qobiliyati, yuqori mexanik kuch va ishonchli elektr ishlashi bilan quruq turdagi transformator mahsulotini tanladingiz.

In order to enable you to use this product effectively and reliably, please install, inspect and maintain the product according to the contents of this Manual.

KATALOG

Mahsulot haqida umumiy ma’lumot

Ish sharoitlari

Asosiy texnik parametrlar

Model tavsifi

Mahsulot tizimining tavsifi

Mahsulotni qadoqlash va tashish

Tekshirish va qabul qilish

O’rnatishdan oldin vizual tekshirish

Ishga tushirishdan oldin tekshirish sinovi

Tarmoqning ishlashi

saqlash

Xavfsizlik muhim

1. Mahsulotlarga umumiy nuqtai

SCB series resin-insulated dry-type power transformers have the advantages of safety, reliability, energy saving and easy maintenance. Considering economical safety and environmental applicability, this series of transformers have wide application prospects. The product design is advanced, the process is strict, and the test is perfect. The high-voltage winding adopts high-quality conductors,and excellent insulating material made by vacuum casting and curing. The low-voltage winding is wound with high-quality foil material, and the iron core is made of high- quality high-permeability cold-rolled silicon steel sheet, which is made with excellent technology. Therefore, the product has high mechanical strength and electrical strength, and has very good heat dissipation performance, the product has small partial discharge, high reliability, long operating life, no moisture absorption, flame retardant, explosion-proof, no pollution, low loss, Light weight, automatic temperature control saves installation space, maintenance costs, and electricity. It can penetrate into the load center and is suitable for urban construction, high-rise buildings, commercial centers, residential quarters, entertainment and sports centers, hospitals, tourist buildings, airports, ports, railway stations, subways, highway tunnel civil air defense facilities, petrochemical enterprises, electro-chemical enterprises, food industry, sewage purification, offshore oil platforms, mines and other places.

2. Ish sharoitlari

2.1 The altitude of the installation site should not exceed 1000m, and the ambient temperature should not be higher than 40°C (special customization can be made if this requirement is exceeded).

2.2 Foydalanish muhiti: nisbiy namlik 100%, atrof-muhit harorati: +40 ° C dan -5 ° C gacha (-5 ° C yopiq transformatorlar uchun mos keladi).

2.3 This product is generally an indoor type. The installation site should be clean,

begona moddalar, chang va korroziy gazdan xoli va yaxshi shamollatish sharoitlariga ega. Agar u podvalda yoki boshqa yomon havalandırılan joylarda o’rnatilgan bo’lsa, majburiy shamollatish muammosini ko’rib chiqish kerak. IKW uchun ushbu mahsulotning yo’qolishi (yuksiz yo’qotish + yukni yo’qotish) taxminan 3-4 m3 / min shamollatish.

2.4 Mahsulot o’rnatilganda, korpus odatda 800 mm masofada bo’lishi kerak

devordan va boshqa to’siqlardan va 300 mm masofada bo’lishi kerak

qo’shni transformator korpuslari o’rtasida.

2.5 Oddiy sharoitlarda transformator to’g’ridan-to’g’ri foydalanish joyiga joylashtirilishi mumkin va o’rnatish va tekshirishdan so’ng foydalanishga topshirilishi mumkin. Vibratsiyaga qarshi va boshqa maxsus talablarga ega bo’lgan holatlar uchun transformator o’rnatiladigan poydevor murvat bilan o’rnatilgan bo’lishi kerak, transformator esa murvat va yong’oqlar bilan o’rnatilishi kerak.

3. Asosiy texnik parametrlar

3.1 Rated frequency: 50Hz

3.2 Cooling method: AN (AF) or according to user requirements

3.3 Qobiq himoya darajasi: IP20 yoki foydalanuvchi talablariga muvofiq.

3.4 Ulanish guruhi yorlig’i: Dyn11 yoki foydalanuvchi talablariga muvofiq.

3.5 Transformer phase sequence: facing the high-voltage side of the transformer from left to right, the high-voltage side is ABC, and the low-voltage side is a(o)bc.

3.6 O’rash izolyatsiyasi sinfi: F sinfi yoki foydalanuvchi talablariga muvofiq.

3.7 Izolyatsiya darajasi

10kV toifadagi mahsulotlarning quvvat chastotasi chidamliligi 35kV, impulsga chidamliligi esa 75kV. 20kV toifali mahsulotlarning quvvat chastotasi chidamliligi 50kV, impulsga chidamliligi 125kV, 30kV toifadagi mahsulotlarning quvvat chastotasi chidamliligi 70kV, impulsga chidamli kuchlanish esa 170kV.

3.8 Haroratning ko’tarilish chegarasi:

Izolyatsiya tizimining harorati (C): 155. Maksimal harorat ko’tarilishi (k): 100.

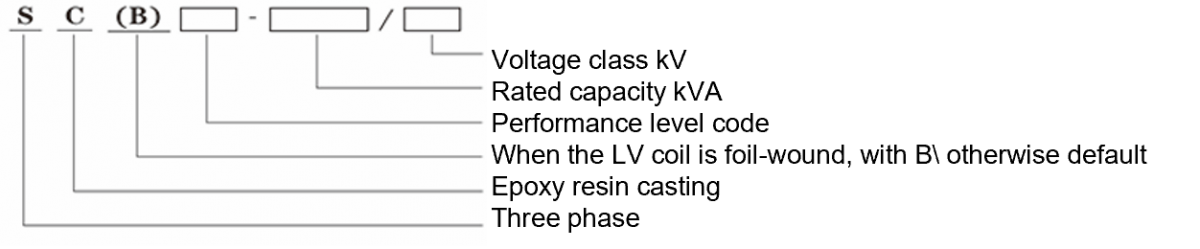

4. Model tavsifi

5. Product system description

5.1 Temperature display and temperature control system

This product can be equipped with a temperature display temperature control system according to the user’s requirements, and its functions are:

(1) Detect the coil temperature when the transformer is running, and display it

avtomatik ravishda.

(2) Fanni ishga tushirishga sozlang va lasan harorati 80 °C ga yetganda fanni ishga tushiring (standart qiymat, sozlanishi).

(3) Haddan tashqari harorat signali, lasan harorati 130 °C ga yetganda (standart qiymat, sozlanishi), signal signali beriladi.

(4) Haddan tashqari harorat rejimi, chiziqning atrof-muhit harorati oshib ketganda

150 °C (standart qiymat, sozlanishi), chiqish signali chiqariladi.

(5) Signal termometrining belgilangan chegarasi oshib ketganda, fan bo’lishi mumkin

started and stopped, the power supply can be cut off, and the transformer can be protected.

5.2 Sovutish tizimi Sovutish usuli o’z-o’zidan sovutish (AN). O’z-o’zidan sovutish vaqtida chiqish quvvati 100% ni tashkil qiladi va majburiy havo aylanishini sovutish (AF) vaqtida qisqa muddatli ortiqcha yuklashga ruxsat beriladi.

5.3 Degree of protectionWhen the transformer is not equipped with a casing, the protection grade is IP00 for indoor use; if the user needs it, it can be equipped with a casing, that is, IP20 or IP30 or IP40 (when the transformer protection grade is high, the transformer should be considered for derating operation).

Eslatma: IP20 muhofazasi 12 mm dan katta qattiq begona jismlarning kirib kelishiga to’sqinlik qilishi va oqim o’tkazuvchi qismi uchun xavfsizlik to’sig’ini yaratishi mumkin. IP30 himoya qobig’i 2.5 mm dan katta begona narsalarning kirib kelishiga to’sqinlik qilishi mumkin. 1P40 qobig’i 1 mm dan katta begona narsalarning kirishiga to’sqinlik qilishi mumkin.

6. Product packaging and transportation

6.1 Mahsulotlar ikki turga bo’linadi: odatda temir yo’l, suv va avtomobil yo’llari orqali tashiladigan ochiq turdagi (himoya qoplamasisiz) va himoya turi (himoya qoplamasi bilan). Kalitlar, termostatlar, havo sovutish moslamalari, tashqi himoya asboblari va boshqalar alohida-alohida) yoki tashish uchun butunlay qadoqlangan bo’lishi kerak. Mahsulotlarni ko’tarish va tushirish uchun kranlar, vinchlar yoki boshqa tegishli transport vositalaridan foydalanish mumkin.

6.2 Mahsulotni tashish paytida yomg’ir suvining cho’kib ketishiga yo’l qo’ymaslik uchun yomg’irga chidamli choralar ko’rish kerak.

6.3 In the process of lifting and transporting products with packaging boxes, the ropes should be hung on the sleepers at the four corners of the bottom of the packaging box, and the unpackaged products should be lifted with special lifting devices, which can be lifted 100mm-150mm from the ground first, and then formally Lifting.

6.4 Tashish paytida, tashish liniyasida 15 ° dan ortiq yuqoriga va pastga qiyaliklar bo’lmasligi kerak. Avtotransport vositasi yukni bir tekisda ko’tara olishini ta’minlash uchun mahsulotning og’irlik markazi yuklash vaqtida transport vositasining vertikal o’rta chizig’ida joylashgan bo’lishi kerak. Oldini olish uchun

tashish paytida mahsulotni almashtirish va ag’darish, mahsulotning uzun o’qining yo’nalishi transport yo’nalishiga mos kelishi va mahsulot transport vositasiga mahkam bog’langan bo’lishi kerak.

6.5 Kransiz yuklash va tushirishda xavfsizlik texnik talablariga rioya qilish kerak va yuk ko’tarish qobiliyati mahsulotning transport og’irligiga mos keladimi yoki yo’qligini tekshirish kerak.

6.6 For products with a trolley required by the user, a trolley with rollers is installed at the bottom, which is generally unloaded during transportation to ensure the stability of the product transportation. After arriving at the destination, it is reset and installed before installation. Products with a trolley. By changing the direction of the roller shafts at both ends of the frame by 90°,

mahsulot gorizontal yoki vertikal ravishda harakatlanishi mumkin.

6.7 Mahsulot belgilangan joyga yetkazilgandan so’ng, transport holatida to’xtash vaqtini iloji boricha qisqartirish kerak (ochiq havoda to’xtashdan saqlaning). O’rnatishdan oldin uni iloji boricha yopiq, quruq va havalandırılan joyda qo’yish kerak. Shu bilan birga, mahsulotni o’g’irlashga, namlikka chidamli va changga, axloqsizlikka, zarbaga, shikastlanishga va kirga qarshi choralar ko’rish kerak.

7. Inspection and acceptance

7.1 Mahsulotni qabul qilgandan so’ng, foydalanuvchi tekshirish va qabul qilish uchun qutini o’z vaqtida ochishi, qadoqlash ro’yxatida sanab o’tilgan narsalar to’liq yoki yo’qligini tekshirishi, tashish paytida transformatorning shikastlanganligini, mahsulot qismlari shikastlangan va joyidan joy olganligini tekshirishi kerak va mahkamlagichlar bo’shashganmi, izolyatsiya buzilganmi va ifloslanish izlari bormi va hokazo.

7.2 Mahsulot nom plaketidagi ma’lumotlar foydalanuvchi tomonidan belgilangan mahsulot spetsifikatsiyasi, quvvati, kuchlanish darajasi, ulanish guruhi yorlig’i, qisqa tutashuv empedansi va hokazolarga mos kelishini tekshiring.

7.3 Mahsulot qadoqdan chiqarilgandan va tekshirilgandan so’ng, agar u darhol ishga tushirilmasa, uni qayta qadoqlash va xavfsiz yopiq joyga qo’yish kerak (o’g’irlashga qarshi, namlikka chidamli, changga chidamli, ifloslanishga qarshi, to’qnashuvga qarshi) mahsulotni saqlash haqida ogohlantirish.

7.4 Transformatorni qabul qilish transport bo’limi bilan birgalikda tegishli topshirish xatida imzolanadi. Tasdiqlash xatida tekshirish paytida aniqlangan muammolar aks ettirilishi kerak.

7.5 Tekshiruv davomida qadoqlash qutisi va mahsulot jiddiy shikastlanganligi aniqlansa, transport va sug’urta bo’limlari darhol xabardor qilinishi kerak va saytni utilizatsiya qilish uchun saqlash kerak.

8. O’rnatishdan oldin vizual tekshirish

8.1 Qutini ochgandan so’ng, tashqi holatni tekshirish uchun himoyalarni (agar mavjud bo’lsa) echib oling, ayniqsa bobin va yadroning mexanik yaxlitligiga, sim doirasi va yadroning siqilish darajasiga va simning mahkamlanishiga e’tibor bering. murvatlar ulanishdan tashqarida.

8.2 Tekshiruvdan so’ng barcha mahkamlagichlar va rulonlarning siqish qismlari va temir yadrolari ketma-ketlikda qayta tortilishi kerak va bo’shashishga yo’l qo’yilmaydi.

8.3 Zavodning texnik shartlari qoidalariga va transformator korpusiga o’rnatilgan komponentlarning to’liq to’plamining tegishli ko’rsatmalariga muvofiq demontaj qilingan qismlarni qayta o’rnating.

8.4 Mahsulotdagi chang va axloqsizlik uchun quruq siqilgan havodan foydalanishga harakat qiling. Maxsus holatlarda, masalan, latta bilan tozalashda mato quruq, toza va tuklarsiz bo’lishi kerak.

8.5 Saqlash muddati uzoq bo’lsa, transformator yuzasida suv tomchilari yoki jiddiy kondensatsiya mavjud bo’lsa, siz quruq ishlov berishingiz kerak va bobinning izolyatsiyalash ko’rsatkichlari malakali bo’lgandan keyin ishlatilishi mumkin.

9. Ishga tushirishdan oldin tekshirish sinovi

9.1 Yuqori va past kuchlanishli sariqlarning shahar qarshiligini o’lchash (ma’lumotlar zavod sinov sertifikatida berilgan ma’lumotlarga mos keladimi).

9.2 Temir yadroning yerga ulanishini tekshiring (yerga ulash qismi odatda pastki temir bo’yinturuq yoki yuqori temir bo’yinturug’ning oxirida joylashgan), topraklama ishonchli yoki yo’qligini, begona moddalarning bir-biriga yopishganligini va ko’p tarmoqli mavjudligini tekshiring. -nuqta topraklama hodisasi.

9.3 Izolyatsiya qarshiligini o’lchash

| Voltage class | 10kV | 20kV | 30kV |

| High voltage coil to low voltage coil | 500MΩ | 800MΩ | 1000MΩ |

| High voltage coil to ground | 500MΩ | 800MΩ | 1000MΩ |

| Past kuchlanishli lasan (0.4V) erga | 50MΩ | 50MΩ | 50MΩ |

| Core to ground | 5MΩ | 5MΩ | 5MΩ |

9.4 When doing the power frequency withstand voltage test, the temperature control probe wire should be taken out from the wire enclosure to prevent the breakdown of the internal components of the thermostat, and even the breakdown of the transformer coil.

9.5 Himoya tizimining yaxshi holatda yoki yo’qligini tekshiring.

9.6 Transformatorni o’rnatish joyi devordan va issiqlik tarqalish sharoitlariga ta’sir qiluvchi boshqa narsalardan kamida 800 mm masofada joylashgan bo’lishi kerak. Transformator o’rnatilgandan so’ng, ishonchli topraklama uchun topraklama murvatlari umumiy topraklama sxemasiga ulanishi kerak.

10. Network operation

10.1 Yordamchi himoya moslamasi va monitoring tizimi erga ulangan va malakali bo’lgandan so’ng, transformator birinchi navbatda yuksiz ishlashi kerak va uch marta zarbalar yopilgandan so’ng, o’rni himoyasi tizimini tekshiring va sozlang.

10.2 Mahsulot zavoddan chiqqandan so’ng, yuqori bosim tomonining kran pozitsiyalari nominal qiymat holatiga ko’ra ulanadi. Ish paytida kuchlanishni sozlash talab qilinadi. Mahsulotning nom belgisida ko’rsatilgan kran kuchlanishiga ko’ra, uch faza bir vaqtning o’zida mos keladigan kran aloqasida (qo’zg’alish va kuchlanishni tartibga solish bo’lmasa) o’rnatiladi va transformatorning quvvat manbai uziladi.

10.3 The transformer adopts the BWDK series thermostat, and the temperature measuring element is embedded in the upper end of the low-voltage coil, which can automatically detect and display the respective working temperatures of the three-phase coils. When the coil temperature reaches the set temperature, the thermometer can automatically start the fan, stop the fan, alarm, trip, and the set temperature can be adjusted by the user.

11. saqlash

Quruq turdagi transformator bir muddat ishlagandan so’ng, quvvatni uzib qo’yish va quyidagi zarur tekshiruvlar va texnik xizmat ko’rsatishni amalga oshirish kerak.

11.1 Turli qismlarda bobinlar, muhrlangan simlar, kran terminallari va mahkamlagichlarni shikastlanish, deformatsiya, bo’shashish, rang o’zgarishi, tushirish izlari va korroziya uchun tekshiring. o’lchov.

11.2 Transformatordan changni olib tashlang. Qo’l tegishi mumkin bo’lgan barcha qismlar toza, tuklarsiz quruq mato va boshqalar bilan artib tashlanishi kerak, lekin uchuvchi tozalagichlardan foydalanmaslik kerak. Temir yadroli rulon ichidagi artib tashlash qiyin bo’lgan qismlar uchun changni puflash uchun quruq siqilgan havo ishlatilishi kerak.

11.3 Ventilyator bilan jihozlangan transformator fandagi chang va tuproqni ham olib tashlashi kerak (fanning pichoqlari shikastlanganligi sababli deformatsiyalanishidan ehtiyot bo’ling) va fan podshipnikining moylanishini tekshirishi, kerak bo’lganda uni to’ldirishi yoki almashtirishi kerak.

11.4 Tekshirish va texnik xizmat ko’rsatish tugallangandan so’ng, transformatorni qayta ishga tushirishdan oldin, lasan va temir yadroda va izolyatsion qismlarda tushib qolgan metall yoki metall bo’lmagan begona moddalar bor-yo’qligini diqqat bilan tekshirish kerak.

12. Xavfsizlik masalalari

12.1 The power supply of the temperature controller (and the fan) should be obtained through the switch screen, not directly connected to the transformer.

12.2 Transformatorni ishga tushirishdan oldin transformator xonasining topraklama tizimini tekshirish kerak.

12.3 The door of the transformer enclosure should be closed to

elektr energiyasidan foydalanish xavfsizligini ta’minlash.

12.4 Baxtsiz hodisalardan qochish uchun kichik hayvonlarning transformator xonasiga kirishiga yo’l qo’ymaslik choralari bo’lishi kerak.

12.5 Transformator xonasiga kirayotganda xodimlar izolyatsion poyabzal kiyishlari, oqim o’tkazuvchi qismidan xavfsiz masofaga e’tibor berishlari va transformatorga tegmasliklari kerak.

12.6 Transformatorning shovqini to’satdan kuchayishi aniqlansa, siz transformatorning yuk holatiga va elektr tarmog’ining kuchlanishiga e’tibor qaratishingiz, transformator haroratining o’zgarishiga e’tibor berishingiz va tegishli xodimlarga murojaat qilishingiz kerak. o’z vaqtida maslahatlashish.

12.7 Transformatorning normal ishlashini ta’minlash uchun transformatorni 1-2 yil davomida muntazam ravishda tekshirish va texnik xizmat ko’rsatish kerak.

12.8 O’rnatish, sinovdan o’tkazish, foydalanish va texnik xizmat ko’rsatish

transformator malakali mutaxassislar tomonidan amalga oshirilishi kerak.