- 06

- Jan

I-10 kV 11 kV Umyalelo woFakelo lweTransformer yoHlobo olomileyo, i-SPL-Electric

1. Injongo yokuhlanganisa

This work guide is applied to the installation and live test of dry-type transformers in the construction of 10kV power distribution room.

2. Isiseko sokulungiselela

2.1 “Standards for Quality Inspection and Evaluation of Thermal Power Construction” for electrical installations;

2.2 SCB10 series dry-type transformer product instruction manual;

2.3 “Safety Work Rules for Electric Power Construction”;

2.4 Imizobo yoyilo lolwakhiwo lwale projekthi (umthamo wombane);

2.5 “Technical Specifications for Construction and Acceptance of Electric Power Construction”

3. Umxholo wolwakhiwo kunye netshati yokuhamba komsebenzi

Low-voltage desulfurization transformer inspection, drying, body installation and transformer accessories installation, live test run.

picture

4. Iimeko zokwakha

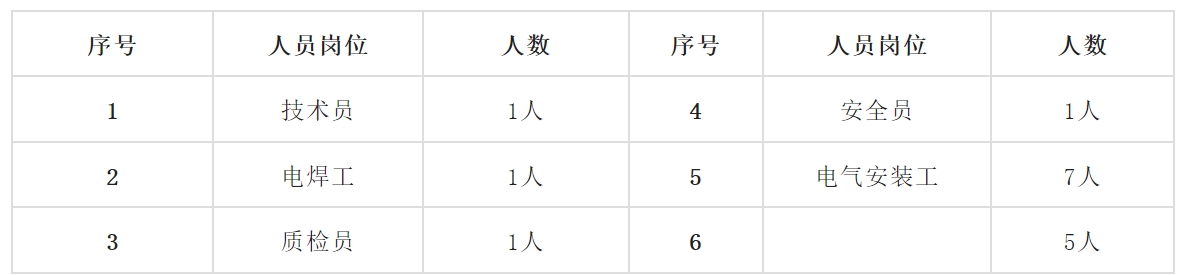

4.1 Abasebenzi:

4.2 Conditions to be met

4.2.1 The civil work has been completed, the site is cleaned up, and the ground elevation is marked on the wall.

4.2.2 Imiyalelo yomsebenzi yenziwe yaza yavunywa.

4.2.3 Amagcisa aququzelela abasebenzi bokwakha ukuba baqhelane nemizobo yokwakha kunye nedatha yobugcisa, kwaye benze ukubhengezwa kobugcisa, kwaye ukubhengezwa kokhuseleko kugqityiwe.

4.2.4 I-transformer inikezelwe kwindawo.

4.2.5 Yenza uhlolo lokungapakishi kunye nokwamkelwa kunye namasebe afanelekileyo, kwaye wenze iirekhodi.

5. Iinkqubo zokwakha kunye neendlela

5.1 Inkqubo yokwakha:

Construction preparation Foundation channel steel production and installation Transformer secondary transportation Transformer unpacking inspection Transformer in place Bus bridge installation Bus connection Inspection of transformer after installation.

5.2 Construction method

5.2.1 Production of basic section steel.

5.2.2 Fumana i-#8 yentsimbi yentsimbi njengentsimbi yecandelo elisisiseko ngokwenkcazo yoyilo.

5.2.3 Beka intsimbi yetshaneli kwiqonga elithe tye kwaye usebenzise isando sokuyilungisa. Emva kokuhlolwa, ukungalingani kunye nokuthe tye kwimitha nganye kungaphantsi kwe-1.5mm.

5.2.4 Sebenzisa isarha engenamazinyo ukusika imathiriyeli ngokobungakanani bokuyila, kwaye usebenzise igrinder okanye ifayile ukucoca iibhutsi kumphetho wesarha ukuze zibe mpuluswa.

5.2.5 Hlanganisa isakhelo sesinyithi esineprofayili, sebenzisa umlinganiselo we-tape yensimbi ukuze ufumane impazamo ye-diagonal yefreyimu yensimbi yeprofayili ayikho ngaphantsi kwe-5mm, sebenzisa inqanaba lokubona ukuchaneka kunye nokungalingani kwensimbi egciniweyo (kungekho ngaphezu kwe-1.5mm nganye imitha, kwaye ingabi ngaphezu kwe-5mm ubude obupheleleyo). Emva kokuba beqeqeshiwe, badityaniswa kunye, baphinde bahlolwe kwakhona, kwaye badityaniswe ngokuqinileyo emva kokudlula.

5.2.6 Sebenzisa ibrashi yentsimbi ukususa umhlwa kwintsimbi yecandelo, uze ke usebenzise umaleko wepeyinti yelothe ebomvu ukwenzela i-anticorrosion emva kokuveza i-metallic luster, uze ufake ipeyinti yokugqiba efana okanye efana nombala we-metallic. izixhobo.

5.3 Basic section steel installation

5.3.1 Qhagamshelana namacandelo afakwe ngaphambili kwisebe lokucoca ubunjineli boluntu, kwaye umaka indawo yokugqibela yomgangatho wangaphakathi wangaphakathi ngexesha elinye, kwaye ufake intsimbi esisiseko ngokomzobo we-transformer layout ekhutshwe liziko loyilo.

5.3.2 Ngomgca osembindini wesakhiwo njengomgca ohambelanayo, fumana umgca we-datum wofakelo lwensimbi (impazamo ayikho ngaphezu kwe-5mm), thatha umgangatho wokugqibela wangaphakathi wangaphakathi njengoko uphawulwe yi-civil engineering kunye ne-5mm njengendiza ephezulu. i-datum yensimbi esisiseko, kwaye usebenzise inqanaba lomoya okanye i-U-shaped Emva kokuba indlela yenqanaba lombhobho ifanelekile, i-welding iqinile. Kuzo zombini iziphelo zesiseko seplate kunye nebhuloho yebhasi, ingqalelo kufuneka ihlawulwe kwisithuba kunye nokuhambelana kwentsimbi yentsimbi phakathi komnye nomnye. Ukufakela isiseko sentsimbi yentsimbi kuya kuhambelana nemimiselo.

5.3.3 Weld 8 pieces of hot-dip galvanized round steel or -40×6 hot-dip galvanized flat steel at both ends of the foundation, and connect with the main grounding grid. Twice the width; small openable doors equipped with electrical appliances shall be reliably grounded with bare copper flexible wires and grounded metal frames.

5.3.4 All welds shall be repainted after removing the coating.

5.4 Ukuhlolwa kokungapakishi kweTransformer

5.4.1 Xa uvula ibhokisi ukuze ihlolwe, kufuneka kubekho abasebenzi abafanelekileyo.

5.4.2 Okokuqala jonga ukuba ukupakishwa kugqityiwe na kwaye akonakaliswanga, vula ibhokisi uze ukhangele uze ubale. Iimpawu, iimodeli, kunye nobuninzi be-transformers kunye neepaneli ze-low-voltage kufuneka zihlangabezane neemfuno zoyilo. Izixhobo kunye neendawo ezisecaleni kufuneka zizaliswe. Iirekhodi kufuneka zigcinwe ukuze zihlolwe ukupakishwa, iingxaki zomgangatho kufuneka ziphakanyiswe kwangethuba, kwaye iirekhodi zokuhlolwa kokukhutshwa kufuneka zenziwe.

5.5 Uthutho lwesibini lweziguquli

5.5.1 Ngaphambi kokuthutha, khangela uhlobo kunye nobuninzi be-transformer.

5.5.2 The transformer is transported by car, there should be no serious impact and vibration during transportation, and it should be fixed firmly during transportation to ensure safety.

5.5.3 In the process of transportation, special personnel should be supervised to prevent tilting.

5.5.4 Xa i-transformer ikhutshwe, kufuneka ikhutshwe ngokuthe ngqo kwii-roller bar ezibekwe ngaphambili. Isalathiso se-transformer kufuneka sibekwe ekuqwalaseleni ulwalathiso lokufakela, kwaye i-transformer kufuneka ithintelwe kwi-sliding xa ibeka i-transformer.

5.5.5 When the shell of the dry-type transformer can be disassembled, the shell should be dismantled first. When dismantling, it should be marked to avoid wrong installation. When dismantling, the observation window glass should be prevented from being damaged.

5.5.6 Xa i-transformer itsalwa, amanyathelo okukhusela kufuneka athathwe, njengokubeka izikhumba zerabha, ukukhusela umonakalo emhlabeni. Kufuneka kuthathelwe ingqalelo ukuthintela ukubamba amajiko-jiko agqunyiweyo xa urhuqwa.

5.5.7 Amandla ngexesha lokutsala kufuneka afane, angaguquguquki kwaye alungelelaniswe, kwaye ukutsala kufuneka kucothise ukuthintela ukuthambeka.

5.5.8 Construction should be carried out under unified command, pay attention to safety, and prevent hands and feet from being crushed by rolling bars.

5.6 Ufakelo lwesiguquli sohlobo olomileyo

5.6.1 Remove the packing box of the dry-type transformer, hang it on the roller bar, and slowly push it to the side of the channel steel foundation. If necessary, it can be pulled by a hoist on the lock frame at the lower 1/3 of the transformer.

5.6.2 Xa i-transformer eyomileyo igxininiswe ngokuthe ngqo kwintsimbi yecandelo, sebenzisa isibonda esinemilenze emithathu kunye ne-hoist ukuphakamisa i-transformer endaweni, sebenzisa inqanaba lomoya, i-plumb line, kunye nerula yensimbi ukulinganisa ukuphambuka. kwindawo, kwaye usebenzise indlela yokukhuselwa ukunciphisa ukutenxa ukuya kuluhlu olugqwesileyo. Sebenzisa i-welding yombane phakathi kweentsimbi ezincinci kunye naphakathi kwentsimbi encinci kunye nentsimbi esisiseko, kwaye wenze amanqaku ahambelanayo kwisiseko se-transformer. Ngokuqhelekileyo, akufuneki kubekho ii-gaskets ezingaphezu kwe-3, kwaye i-gaskets ayifanele ibonakaliswe ngaphandle kwesiseko.

5.6.3 Use a marking pen to mark the corresponding position of the fixing hole of the base, remove the transformer, use an aircraft drill to drill 11 holes at the marked place, and use an M12 tap to tap the hole, the transformer is in place here, and after alignment, use an M12X40 plating Zinc bolts are fastened after passing through 12 square inclined washers.

5.6.4 Xa i-transformer ifakwe kwisigqubuthelo sokukhusela, lungisa kuqala isigqubuthelo sokukhusela ngokwendlela yepleyiti ethe nkqo, emva koko usebenzise i-tripod pole ukuphakamisa ii-roller zokufakela i-transformer, kwaye ulungelelanise isalathiso samacala aphezulu kunye aphantsi (ukuba kukho Alulo uyilo, lulungele ibar yebhasi esecaleni enevoltage ephantsi kunye nekhabhathi yomgca engenayo) Idokhi yebhasi yangaphakathi iyakoyisa), seta uxinzelelo lokutsaleka phambi kocango olukhuselayo, eyona ndawo iphezulu yoxinzelelo kukugungxulwa komphetho Umkhondo wangaphakathi wesigqubuthelo esikhuselayo, uyityhale kumzila wenguqu, uhlengahlengise umbindi womxhuzulane we-transformer ukuze ihambelane nombindi wesigqubuthelo esikhuselayo, kwaye ubambe ibholithi ngesivalo Idityaniswe kumzila ukwenza ibrake yerola. ngokuthembekileyo.

5.6.5 Thumela imitha kwigumbi lokulinganisa imitha ukuze ihlolwe, kwaye uyilungise kwindawo echongiweyo kumzimba we-transformer emva kokuphumelela uvavanyo. Ufakelo lunqanaba kwaye luqinile.

5.6.6 Izixhobo zentsimbi zegobolondo eliphezulu lomzimba we-transformer-type dry kunye ne-grounding point of iron core zenziwe ngee-multi-strand copper core wire kunye ne-cross-section ye-1x50mm2 okanye ngaphezulu. Emva kokucinezela iimpumlo zobhedu ezinkonkxiweyo kuzo zozibini iziphelo, zikrwelwa kwintsimbi ephantsi, kwaye amajoyinti aqatywe ngegrisi edibeneyo yombane. Indawo engathathi hlangothi ye-transformer yohlobo olumileyo kufuneka ixhunywe kumnatha osisiseko osisiseko ngokweemfuno zoyilo emva kokudlula kwi-zero-sequence current transformer.

5.6.7 Sebenzisa izibophelelo zegalvanized, iindawo ezikhululekileyo kufuneka ziboshwe, kwaye ubude obuveziweyo bamazinyo e-screw kufuneka kube ngamaqhosha ama-3 ukuya kuma-5.

5.6.8 Carry out the test according to the electrical handover test specification.

5.6.9 After the transformer is in place, do not fix it by welding, and weld together after the low-voltage plate is in place. After the transformer is in place, install the enclosure correctly according to the markings.

6. Iimfuno zobugcisa ezisemgangathweni

6.1 After the foundation channel steel is installed, its top should be 10mm higher than the troweled ground, and the non-straightness and levelness of the foundation should be tested. The full length deviation is less than 5mm.

6.2 Xa iipaneli zifakwe, impazamo yezinga eliphezulu leepaneli ezimbini ezikufutshane zingaphantsi kwe-1 mm, kwaye phezulu kweepaneli ezidibeneyo zingaphantsi kwe-5 mm. Impazamo ethe nkqo kufuneka ingabi nkulu kune-1.5/1000H yobude bayo (H bubude bedisk). Ukungalingani kweediski ezilungiselelwe kumqolo kungaphakathi kwe-5 mm, kwaye ukudibanisa phakathi kweediski kungaphantsi kwe-2 mm.

6.3 Iibholithi, iinati kunye neewasha ezisetyenziselwa ukudibanisa kunye nokulungisa ipaneli ziya kuba ziindawo ezenziwe ngegalvanized, ipeyinti yepaneli iya kuhlala ingaguquki, umphezulu wepaneli uya kuhambelana, kwaye ulungelelwaniso luya kucoceka.

6.4 The connection of the bus bar should be good, and the insulating support and installation parts should be firm and reliable.

6.5 The distance between the secondary electrified body and the elevator to the ground is not less than 4 mm, and the surface leakage distance is not less than 6 mm.

I-6.6 1000V megohmmeter ukujonga ukufakwa kwebhasi, kufuneka ibe mkhulu kune-0.5 megohm.

6.7 All equipment marks, phase color marks, and circuit name marks should be clear and not easy to decolorize.

6.8 Kwizixhobo ezingayi kusetyenziswa ngokukhawuleza emva kokufakwa, amanyathelo okukhusela kufuneka athathwe ukukhusela uthuli kunye nokufuma.

7. Imiqathango yolwakhiwo olukhuselekileyo

7.1 The insulation performance of electric tools should be inspected before use, there should be no leakage, and the shell should be reliably grounded.

7.2 Do not wear gloves when using electric drills.

7.3 Protective measures should be taken to transport the transformer, the transport should be slow to prevent excessive impact, and the crane should use a hydraulic crane with good performance.

7.4 There should be sufficient lighting in the workplace, and the warning signs should be hung up, and a certain number of fire extinguishers should be equipped.

7.5 Abasebenzi bokwakha abangena kwisiza sokwakha kufuneka banxibe iimpahla ezifanelekileyo zokhuseleko kunye nezigcina-ntloko zokhuseleko ngokuchanekileyo. Akuvunyelwe ngokungqongqo ukungena kwindawo yokwakha emva kokusela. Emva kokwakhiwa kwemihla ngemihla, umsebenzi kufuneka ugqitywe, izixhobo kufuneka zicoceke, kwaye indawo kufuneka icoceke.

7.6 Special attention should be paid during the whole construction process, and the lead-out bushing and other accessories should not be damaged.

7.7 Organize construction personnel to study the measures and construction acceptance specifications before construction, and illegal operations are strictly prohibited.

7.8 Ngaphambi kokusebenza kovavanyo oluphilayo lwe-transformer, isiphaluka sesibini kufuneka sihlolwe ukuqinisekisa ukuchaneka kwesekethe yesibini.

7.9 Phambi kokufakelwa kwekhabhinethi yephaneli, umsebenzi woluntu wangaphakathi ugqityezelwe ukuhlangabezana neemfuno zokungangenwa yimvula, ukuthintela ukufuma, ukuchasana nomhlwa, kunye nokuthintela uthuli. Ukuba kuyimfuneko, thatha amanyathelo okwakha isigqubuthelo ukukhusela umonakalo kwikhabhinethi yepaneli.

7.10 Ngexesha lokuthuthwa kwephaneli, kufuneka iyalelwe ngabasebenzi abaqeqeshiweyo abaphakamisayo.

7.11 Emva kokukhupha ikhabhinethi, qaphela ukuyicoca kwangethuba ukuthintela ukuvaleka kwepaseji okanye ukuxinga izikhonkwane.

7.12 When the panel is pried into place, the manpower should be sufficient, and the command should be unified to prevent injury from falling over, and prevent crushing injuries in narrow places.

7.13 When moving the panel, care should be taken to prevent damage to the components and paint on the panel.

7.14 Xa uphehla umzantsi wepani, musa ukufaka izandla zakho emazantsi epani. Xa iipane ezisecaleni zifakwe ecaleni, kufuneka uthintele izandla zakho ukuba zingacinezeli xa uxhomekeke epanini.

7.15 When the panel is fixed, pay attention to the wooden block when hitting the panel with a hand hammer.

7.16

7.17 After the cabinets are in place, safety and security work should be strengthened. It is strictly forbidden for non-staff personnel to enter and exit the power distribution room, and the staff should hold a certificate to work.

7.18 Necessary fire extinguishers should be equipped in the power distribution room.

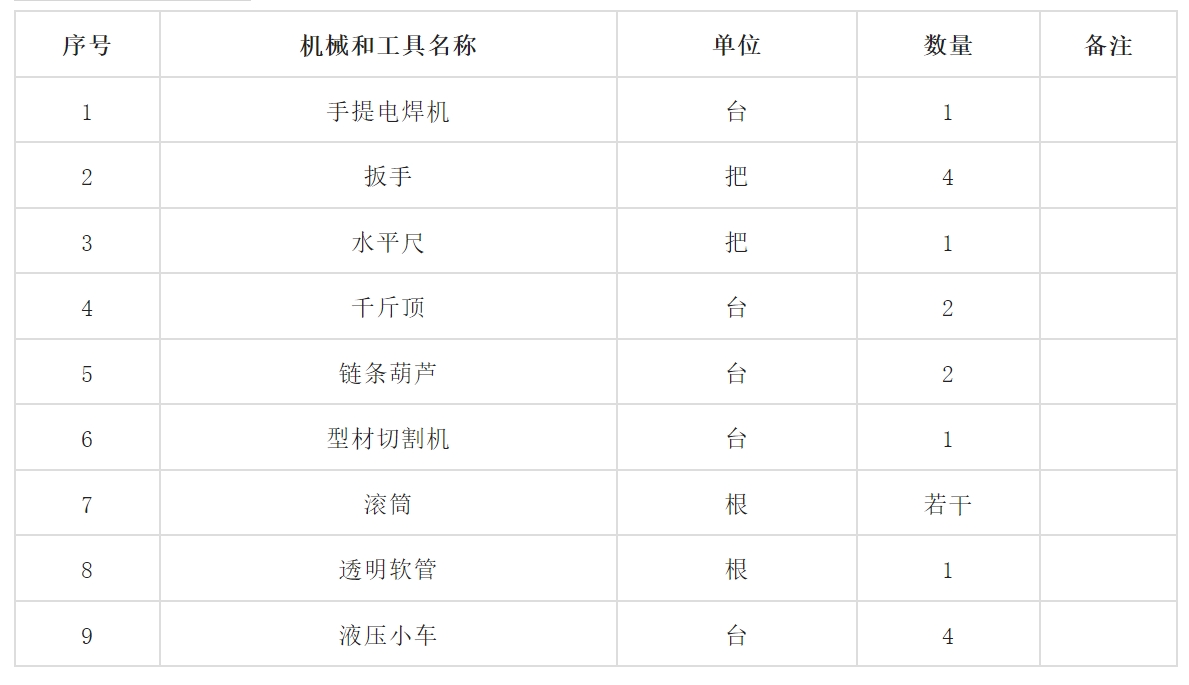

8. Izixhobo eziphambili