- 06

- Jan

10 kV 11 kV Ntuziaka nwụnye ụdị ntụgharị ntụgharị, SPL-Electric

1. Ebumnuche nke nchịkọta

A na-etinye akwụkwọ ntuziaka ọrụ a na ntinye na nyocha ndụ nke ihe ngbanwe ụdị akọrọ na-ewu ụlọ nkesa ike 10kV.

2. ndabere nkwado

2.1 “Ọkọlọtọ maka nyocha nke ọma na nyocha nke nrụpụta ọkụ ọkụ” maka nrụnye eletrik;

2.2 SCB10 usoro akọrọ-ụdị mgbanwe ngwaahịa ntuziaka ntuziaka;

2.3 “Iwu ọrụ nchekwa maka iwu ọkụ eletrik”;

2.4 Construction design drawings of this project (electric volume);

2.5 “Nkọwa nka na ụzụ maka iwu ụlọ na nnabata nke iwu ọkụ eletrik”

3. Ihe owuwu ihe na eserese ọrụ

Low-voltage desulfurization transformer inspection, drying, body installation and transformer accessories installation, live test run.

Foto

4. Ọnọdụ ihe owuwu

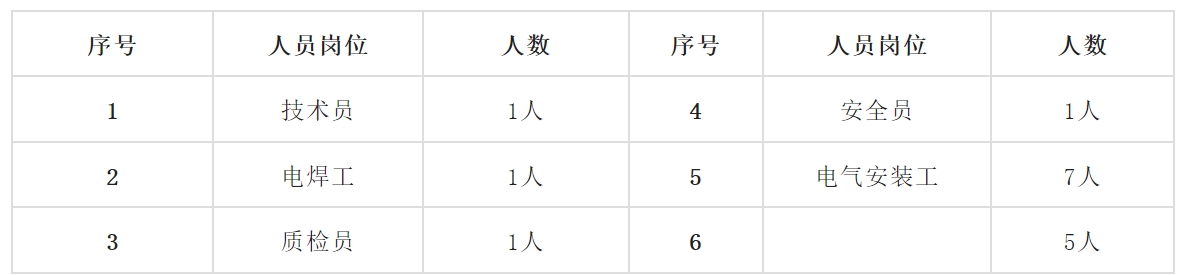

4.1 Ndị ọrụ:

4.2 Ọnọdụ a ga-emezu

4.2.1 The civil work has been completed, the site is cleaned up, and the ground elevation is marked on the wall.

4.2.2 Achịkọtara ma kwado ntuziaka ọrụ.

4.2.3 The technicians organize the construction personnel to be familiar with the construction drawings and technical data, and make a technical disclosure, and the safety disclosure has been completed.

4.2.4 E nyefeela ihe ngbanwe na saịtị ahụ.

4.2.5 Mepụta nyocha na nnabata ọnụ na ngalaba ndị dị mkpa, wee dekọọ ndekọ.

5. Usoro ihe owuwu na ụzọ

5.1 Usoro owuwu:

Construction preparation Foundation channel steel production and installation Transformer secondary transportation Transformer unpacking inspection Transformer in place Bus bridge installation Bus connection Inspection of transformer after installation.

5.2 Construction method

5.2.1 Mmepụta nke isi akụkụ ígwè.

5.2.2 Anata # 8 ọwa ígwè dị ka isi akụkụ ígwè dị ka imewe nkọwapụta.

5.2.3 Put the channel steel on the horizontal platform and use a sledgehammer to straighten it. After inspection, the unevenness and straightness per meter are less than 1.5mm.

5.2.4 Jiri igwe na-enweghị eze na-egbutu ihe ahụ dịka nha nhazi ahụ si dị, ma jiri igwe na-egweri ma ọ bụ faịlụ na-ehicha ihe ndị ahụ n’akụkụ ebe a na-ahụ anya iji mee ka ọ dị nro.

5.2.5 Kpọkọta ọnụ nchara ígwè profaịlụ, jiri ihe nchara ígwè iji chọpụta njehie diagonal nke ọkpụkpụ ígwè profaịlụ abụghị ihe na-erughị 5mm, jiri ọkwa iji chọpụta nzizi na unevenness nke ígwè profaịlụ (ọ bụghị ihe karịrị 1.5mm kwa. mita, na ọ bụghị ihe karịrị 5mm na ngụkọta ogologo). Mgbe ha tozuru oke, a na-ejikọta ha ọnụ, nyochaa ọzọ, na ịgbado nke ọma mgbe ha gafesịrị.

5.2.6 Jiri brush ígwè wepụ nchara na nchara nke ngalaba ahụ, wee tinye akwa akwa uhie na-acha uhie uhie maka anticorrosion mgbe ekpughere ọla ahụ, wee tinye agba agba nke bụ otu ma ọ bụ yiri agba nke akụrụngwa.

5.3 Basic section steel installation

5.3.1 Kpọtụrụ akụkụ ndị etinyegoro na ngalaba nhicha nke injinia obodo, wee kaa akara elu ụlọ ime ụlọ ikpeazụ n’otu oge, wee wụnye nchara nchara dị ka eserese okirikiri nhọrọ ukwuu nke ụlọ ọrụ nrụpụta nyere.

5.3.2 With the center line of the building as the parallel line, find the base steel installation datum line (the error is not greater than 5mm), take the final indoor floor elevation as marked by the civil engineering plus 5mm as the upper plane datum of the basic steel, and use a spirit level or U-shaped After the pipe level method is qualified, the welding is firm. At both ends of the plate foundation with busbar bridge, attention should be paid to the spacing and parallelism of channel steel between each other. The embedding of foundation channel steel shall comply with the regulations.

5.3.3 Weld 8 iberibe ọkụ-mikpu galvanized gburugburu ígwè ma ọ bụ -40 × 6 na-ekpo ọkụ-mikpu galvanized ewepụghị ígwè na ma nsọtụ nke ntọala, na jikọọ na isi grounding okporo. Ugboro abụọ n’obosara; Obere ọnụ ụzọ mepere emepe nwere ngwa eletrik ka a ga-atụkwasịrịrị ya na wires ọla kọpa na-agbanwe agbanwe na okpokolo agba gbadoro ụkwụ.

5.3.4 A ga-emezi akwa akwa niile mgbe ha wepụsịrị mkpuchi ahụ.

5.4 Transformer unpacking inspection

5.4.1 Mgbe imepe igbe maka nyocha, ndị ọrụ kwesịrị ekwesị kwesịrị ịnọ.

5.4.2 First check whether the packaging is complete and undamaged, open the box and check and count. The specifications, models, and quantities of transformers and low-voltage panels should meet the design requirements. Accessories and spare parts should be complete. Records should be kept for unpacking inspection, quality problems should be raised in time, and records for unpacking inspection should be made.

5.5 Ụgbọ njem nke abụọ nke transformers

5.5.1 Before transportation, check the type and quantity of the transformer.

5.5.2 A na-ebu ụgbọ ala na-ebugharị na-ebugharị, ọ gaghị enwe mmetụta siri ike na ịma jijiji n’oge njem, na a ga-edozi ya nke ọma n’oge njem iji hụ na nchekwa.

5.5.3 In the process of transportation, special personnel should be supervised to prevent tilting.

5.5.4 Mgbe ebutula ihe ngbanwe ahụ, a ga-ebutu ya ozugbo na igwe rola edobere ya. Ekwesịrị itinye ntụzịaka nke ntụgharị n’uche maka ntụzịaka nrụnye, a ga-egbochi onye na-agbanwe agbanwe ka ọ ghara ịfe mgbe ị na-etinye ihe ntụgharị.

5.5.5 When the shell of the dry-type transformer can be disassembled, the shell should be dismantled first. When dismantling, it should be marked to avoid wrong installation. When dismantling, the observation window glass should be prevented from being damaged.

5.5.6 When the transformer is towed, protective measures should be taken, such as laying rubber skins, to prevent damage to the ground. Care should be taken to prevent touching the insulated windings when hauling.

5.5.7 The force during dragging should be uniform, consistent and coordinated, and the dragging should be slow to prevent tilting.

5.5.8 Construction should be carried out under unified command, pay attention to safety, and prevent hands and feet from being crushed by rolling bars.

5.6 Ntinye nke ihe ngbanwe nke akọrọ

5.6.1 Wepu igbe nkwakọba ihe nke ụdị akọrọ akọrọ, kpọgidere ya n’elu ihe mkpuchi rola, ma jiri nwayọọ nwayọọ na-agbanye ya n’akụkụ nke ntọala nchara. Ọ bụrụ na ọ dị mkpa, ọ nwere ike ịdọrọ ya site na mkpọli na etiti mkpọchi na ala 1/3 nke ihe ntụgharị.

5.6.2 When the dry-type transformer is directly fixed on the section steel, use a three-legged pole and a hoist to lift the transformer into place, use a spirit level, a plumb line, and a steel ruler to measure the deviation in position, and use the method of padding to reduce the deviation to within the excellent range. Use electric welding between the thin iron sheets and between the thin iron and the basic steel, and make corresponding marks on the transformer base. Generally, there should be no more than 3 gaskets, and the gaskets should not be exposed outside the base.

5.6.3 Use a marking pen to mark the corresponding position of the fixing hole of the base, remove the transformer, use an aircraft drill to drill 11 holes at the marked place, and use an M12 tap to tap the hole, the transformer is in place here, and after alignment, use an M12X40 plating Zinc bolts are fastened after passing through 12 square inclined washers.

5.6.4 When the transformer is installed in the protective cover, first fix the protective cover according to the vertical plate method, then use the tripod pole to lift the transformer installation rollers, and adjust the direction of the high and low sides (if there is no design, it is convenient for the low-voltage side busbar and incoming line cabinet) Inner busbar docking shall prevail), set traction stress in front of the protective cover door, the highest point of the stress is flush with the edge of the inner track of the protective cover, push it into the transformer track, adjust the center of gravity of the transformer so that it coincides with the center of the protective cover, and clamp the bolt with a stopper Connected to the track to make the roller brake reliably.

5.6.5 Send the meter to the meter calibration room for inspection, and fix it to the designated place on the transformer body after passing the test. The installation is level and firm.

5.6.6 Ihe ndị na-emepụta ígwè nke elu shei nke akọrọ-ụdị transformer ahụ na ebe mgbakwasị ụkwụ nke ígwè isi bụ nke multi-strand ọla kọpa isi wires na a cross-ngalaba nke 1x50mm2 ma ọ bụ karịa. Mgbe a pịachara imi ọla kọpa nke nwere agba na nsọtụ abụọ ahụ, a na-apịa ya na ígwè dị larịị nke a gbanyere n’ala, a na-ejikwa mmanụ griiz na-ekekọta nkwonkwo ya. Ebe na-anọpụ iche nke ụdị akọrọ akọrọ kwesịrị ijikọ na netwọk ntọala nke isi dị ka ihe a chọrọ n’ichepụta mgbe ọ gafesịrị ihe ntụgharị efu nke usoro efu.

5.6.7 Use galvanized fasteners, the loose parts should be fastened, and the exposed length of the screw teeth should be 3 to 5 buttons.

5.6.8 Mee nnwale ahụ dịka nkọwapụta nnwale aka eletrik si dị.

5.6.9 After the transformer is in place, do not fix it by welding, and weld together after the low-voltage plate is in place. After the transformer is in place, install the enclosure correctly according to the markings.

6. Ogo teknụzụ chọrọ

6.1 Mgbe etinyere nchara nchara ntọala, elu ya kwesịrị ịdị elu 10mm karịa ala troweled, a ga-anwalekwa enweghị isi na larịị nke ntọala ahụ. Ntugharị ogologo zuru ezu bụ ihe na-erughị 5mm.

6.2 Mgbe etinyere oghere ndị ahụ, njehie larịị nke n’elu akụkụ abụọ dị n’akụkụ bụ ihe na-erughị 1 mm, na n’elu ogwe ndị a na-edozi ahụ bụ ihe na-erughị 5 mm. Njehie kwụ ọtọ ekwesịghị ịbụ ihe karịrị 1.5 / 1000H nke ịdị elu ya (H bụ ịdị elu diski). Uneness nke diski a haziri n’usoro dị n’ime 5 mm, na nkwonkwo n’etiti diski na-erughị 2 mm.

6.3 The bolts, nuts and washers used to connect and fix the panel shall be galvanized parts, the paint of the panel shall be intact, the surface of the panel shall be consistent, and the arrangement shall be neat.

6.4 The connection of the bus bar should be good, and the insulating support and installation parts should be firm and reliable.

6.5 Ebe dị anya n’etiti ahụ eletrọnịkị nke abụọ na igwe mbuli elu na ala abụghị ihe na-erughị 4 mm, ebe nkwụsị elu adịghị erughị 6 mm.

6.6 1000V megohmmeter iji lelee mkpuchi ụgbọ ala, ọ kwesịrị ịdị karịa 0.5 megohm.

6.7 Akara akụrụngwa niile, akara agba agba, na akara aha sekit kwesịrị ịpụta nke ọma na ọ dịghị mfe ịgbanwe agba.

6.8 For the equipment that will not be put into operation immediately after installation, protective measures should be taken to prevent dust and moisture.

7. Akpachara anya maka ewu ewu

7.1 The insulation performance of electric tools should be inspected before use, there should be no leakage, and the shell should be reliably grounded.

7.2 Do not wear gloves when using electric drills.

7.3 Protective measures should be taken to transport the transformer, the transport should be slow to prevent excessive impact, and the crane should use a hydraulic crane with good performance.

7.4 There should be sufficient lighting in the workplace, and the warning signs should be hung up, and a certain number of fire extinguishers should be equipped.

7.5 Construction personnel entering the construction site must wear qualified labor protection clothing and safety helmets correctly. It is strictly forbidden to enter the construction site after drinking. After the daily construction, the work should be completed, the materials should be clean, and the site should be clean.

7.6 Special attention should be paid during the whole construction process, and the lead-out bushing and other accessories should not be damaged.

7.7 Organize construction personnel to study the measures and construction acceptance specifications before construction, and illegal operations are strictly prohibited.

7.8 Before the live test operation of the transformer, the secondary circuit should be checked to ensure the accuracy of the secondary circuit.

7.9 Tupu echichi nke panel panel, arụ ọrụ ime ụlọ na-arụ ọrụ ime ụlọ iji mezuo ihe ndị a chọrọ nke mmiri ozuzo, ihe mkpuchi mmiri, mgbochi corrosion, na uzuzu uzuzu. Ọ bụrụ na ọ dị mkpa, mee ihe iji wuo mkpuchi iji gbochie mmebi nke kabinet panel.

7.10 N’oge njem nke panel, ọ ga-enye iwu site n’aka ndị ọkachamara na-ebuli elu.

7.11 After unpacking the cabinet, pay attention to clean it in time to prevent the passage from being blocked or the nails from getting stuck.

7.12 Mgbe a na-edobe panel ahụ, ndị ọrụ kwesịrị ezuru, na iwu ahụ kwesịrị ịdị n’otu iji gbochie mmerụ ahụ ịdaba, na igbochi mmerụ ahụ n’ebe ndị dị warara.

7.13 Mgbe ị na-ebugharị panel ahụ, ekwesịrị ịkpachara anya iji gbochie mmebi nke ihe ndị ahụ na agba na panel.

7.14 Mgbe ị na-akwachi ala nke ite ahụ, etinyela aka gị n’ime ala nke ite ahụ. Mgbe etinyere pans nke nwere otu akụkụ n’akụkụ, ị kwesịrị igbochi aka gị ka ọ ghara ịpịa gị mgbe ị na-adabere na pan ahụ.

7.15 When the panel is fixed, pay attention to the wooden block when hitting the panel with a hand hammer.

7.16 Mgbe etinyere kabinet panel, mechie ọnụ ụzọ panel n’oge, ma kpuchie ya na akwa rọba ma ọ bụrụ na a gaghị arụ ọrụ n’ime obere oge iji gbochie mmetọ nke abụọ.

7.17 Mgbe etinyere kabinet, ọrụ nchekwa na nchekwa kwesịrị iwusi ike. A machibidoro ndị ọrụ na-abụghị ndị ọrụ ịbanye ma pụọ na ụlọ nkesa ike, ndị ọrụ kwesịrị ijide akwụkwọ ikike ịrụ ọrụ.

7.18 Necessary fire extinguishers should be equipped in the power distribution room.

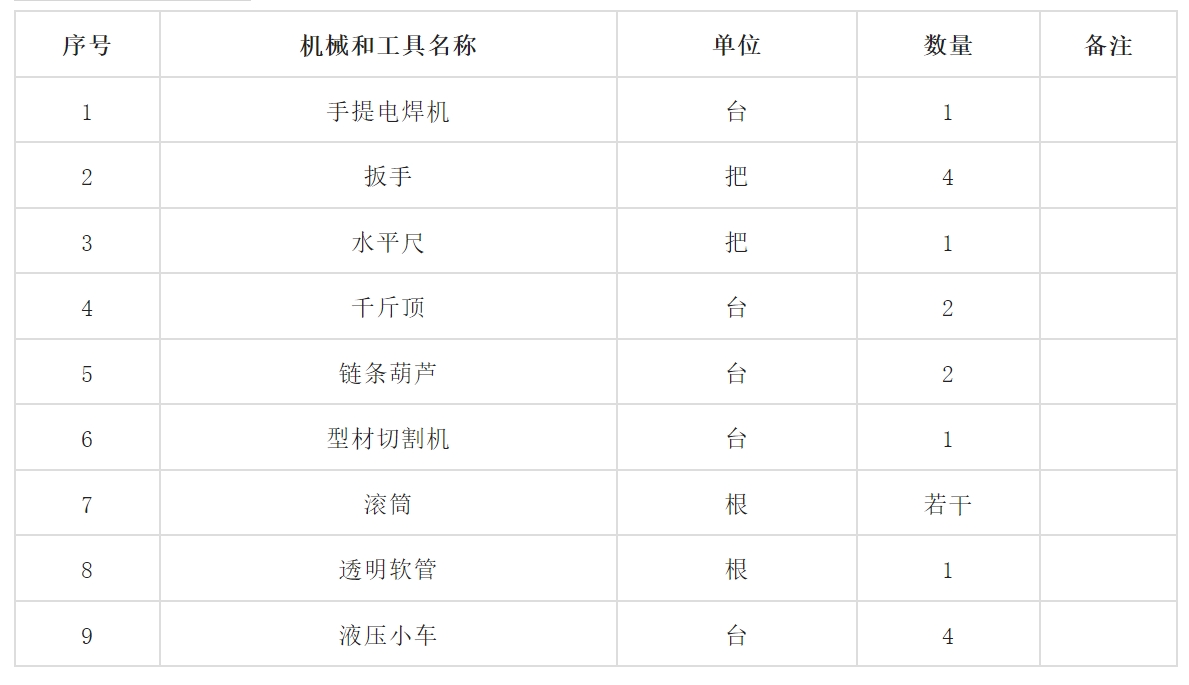

8. Isi ngwá ọrụ