- 06

- Jan

10 kV 11 kV Busassun Nau’in Mai Canja wurin Shigarwa, SPL-Electric

1. Manufar hadawa

Ana amfani da wannan jagorar aikin don shigarwa da gwajin rayuwa na busassun nau’ikan taswira a cikin ginin ɗakin rarraba wutar lantarki 10kV.

2. Tushen shiri

2.1 “Ma’auni don Ingancin Bincike da Ƙimar Gina Ƙarfin Ƙarfafa” don shigarwa na lantarki;

2.2 SCB10 series dry-type transformer product instruction manual;

2.3 “Dokokin Ayyukan Tsaro don Gina Wutar Lantarki”;

2.4 Zane-zane na gine-gine na wannan aikin (ƙarar lantarki);

2.5 “Ka’idodin Fasaha don Ginawa da Karɓar Gina Wutar Lantarki”

3. Construction content and operation flow chart

Low-voltage desulfurization na’urar dubawa dubawa, bushewa, shigar da jiki da na’urorin haɗi shigarwa, gwajin gwajin rayuwa.

hoto

4. Yanayin gini

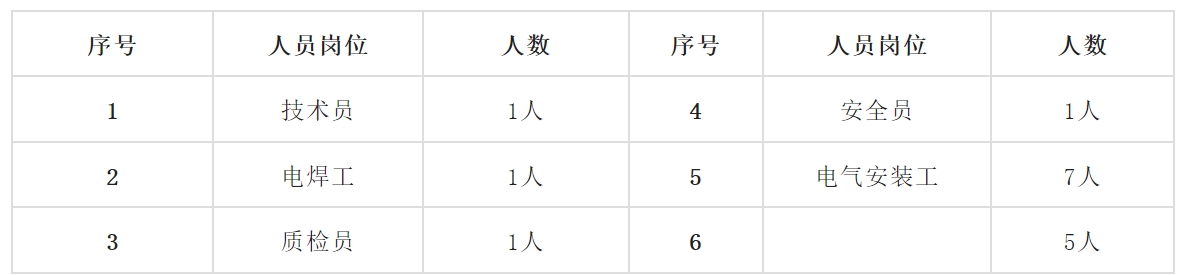

4.1 Ma’aikata:

4.2 Sharuɗɗan da za a cika

4.2.1 An kammala aikin farar hula, an tsaftace wurin, kuma an yi alamar hawan ƙasa a bango.

4.2.2 An haɗa umarnin aikin kuma an yarda da su.

4.2.3 The technicians organize the construction personnel to be familiar with the construction drawings and technical data, and make a technical disclosure, and the safety disclosure has been completed.

4.2.4 An isar da taransfoma zuwa wurin.

4.2.5 Gudanar da dubawa da karɓuwa tare da sassan da suka dace, da yin bayanai.

5. Construction procedures and methods

5.1 Hanyar gini:

Shirye-shiryen Gine-gine tashar tashar ƙarfe samar da shigarwa Transformer secondary Transport Transformer cire kayan dubawa Transformer a wurin Bus gadar shigarwa Bus haɗin Bus Dubawa na transformer bayan shigarwa.

5.2 Hanyar gini

5.2.1 Production of basic section steel.

5.2.2 Karɓi # 8 tashar karfe a matsayin ainihin sashin karfe bisa ga ƙayyadaddun ƙira.

5.2.3 Sanya karfen tashar akan dandamalin kwance kuma yi amfani da guduma don daidaita shi. Bayan dubawa, rashin daidaituwa da madaidaiciya a kowace mita sun kasa da 1.5mm.

5.2.4 Yi amfani da zato mara haƙori don yanke kayan bisa ga girman ƙira, kuma a yi amfani da injin niƙa ko fayil don tsaftace burrs a gefen gani don yin santsi.

5.2.5 Assemble the profiled steel frame, use a steel tape measure to detect the diagonal error of the profiled steel frame is not less than 5mm, use a level to detect the straightness and unevenness of the profiled steel (not more than 1.5mm per meter, and not more than 5mm in total length). After they are basically qualified, they are welded together, re-inspected again, and welded firmly after passing.

5.2.6 A yi amfani da goga na ƙarfe don cire tsatsa a ɓangaren karfe, sannan a shafa fentin jajayen lemar don hana lalacewa bayan bayyanar da ƙarfe, sannan a shafa fenti iri ɗaya ko kama da launin launi. kayan aiki.

5.3 Basic sashe karfe shigarwa

5.3.1 Tuntuɓi ɓangarorin da aka riga aka haɗa na sashin tsabtace injiniyan farar hula, kuma sanya alamar hawan bene na cikin gida na ƙarshe a lokaci guda, kuma shigar da ainihin ƙarfe bisa ga zanen shimfidar canji da cibiyar ƙira ta bayar.

5.3.2 Tare da tsakiyar layin ginin a matsayin layi na layi ɗaya, nemo layin datum ɗin shigarwa na ƙarfe tushe (kuskuren bai fi 5mm girma ba), ɗauki matakin bene na cikin gida na ƙarshe kamar yadda injiniyan farar hula da 5mm a matsayin babban jirgin sama. datum na asali karfe, da kuma amfani da ruhu matakin ko U-dimbin yawa Bayan da bututu matakin Hanyar ne m, waldi ne m. A duka ƙarshen tushe na farantin karfe tare da gadar busbar, ya kamata a biya hankali ga tazara da daidaiton ƙarfe na tashar tsakanin juna. Shigar da ƙarfe na tashar tushe zai bi ka’idoji.

5.3.3 Weld 8 guda na zafi-tsoma galvanized zagaye karfe ko -40 × 6 zafi-tsoma galvanized lebur karfe a duka iyakar kafuwar, da kuma gama da babban grounding Grid. Sau biyu nisa; ƙananan kofofin buɗewa sanye take da na’urorin lantarki za a dogara da su tare da wayoyi masu sassauƙa na tagulla da ƙaƙƙarfan firam ɗin ƙarfe.

5.3.4 Duk welds za a sake fenti bayan cire murfin.

5.4 Duban buɗaɗɗen Transformer

5.4.1 Lokacin buɗe akwatin don dubawa, ya kamata ma’aikatan da suka dace su kasance a wurin.

5.4.2 First check whether the packaging is complete and undamaged, open the box and check and count. The specifications, models, and quantities of transformers and low-voltage panels should meet the design requirements. Accessories and spare parts should be complete. Records should be kept for unpacking inspection, quality problems should be raised in time, and records for unpacking inspection should be made.

5.5 Sufuri na biyu na taransfoma

5.5.1 Kafin sufuri, duba nau’in da adadin na’urar.

5.5.2 The transformer is transported by car, there should be no serious impact and vibration during transportation, and it should be fixed firmly during transportation to ensure safety.

5.5.3 A cikin tsarin sufuri, ya kamata a kula da ma’aikata na musamman don hana karkata.

5.5.4 Lokacin da aka sauke tafsiri, yakamata a sauke shi kai tsaye akan sandunan abin nadi da aka riga aka yi. Ya kamata a sanya alkiblar na’urar ta hanyar la’akari da hanyar shigarwa, kuma ya kamata a hana na’urar ta zamewa yayin sanya na’urar.

5.5.5 Lokacin da harsashi na busassun na’ura mai ba da hanya tsakanin hanyoyin sadarwa za a iya tarwatsa, ya kamata a fara wargaje harsashi. Lokacin tarwatsawa, yakamata a yiwa alama don gujewa shigarwa mara kyau. Lokacin tarwatsawa, yakamata a hana gilashin taga abin kallo daga lalacewa.

5.5.6 Idan aka ja na’urar taranfoma, ya kamata a dauki matakan kariya, kamar shimfida fatun roba, don hana lalacewa a kasa. Yakamata a kula don hana taɓa iskar da aka keɓe lokacin jigilar kaya.

5.5.7 Ƙarfin yayin ja ya kamata ya kasance iri ɗaya, daidaito da daidaituwa, kuma ja ya kamata ya kasance a hankali don hana karkatarwa.

5.5.8 Ya kamata a gudanar da gine-gine a ƙarƙashin umarnin haɗin gwiwa, kula da aminci, da hana murkushe hannaye da ƙafafu ta hanyar birgima.

5.6 Installation of dry-type transformer

5.6.1 Remove the packing box of the dry-type transformer, hang it on the roller bar, and slowly push it to the side of the channel steel foundation. If necessary, it can be pulled by a hoist on the lock frame at the lower 1/3 of the transformer.

5.6.2 When the dry-type transformer is directly fixed on the section steel, use a three-legged pole and a hoist to lift the transformer into place, use a spirit level, a plumb line, and a steel ruler to measure the deviation in position, and use the method of padding to reduce the deviation to within the excellent range. Use electric welding between the thin iron sheets and between the thin iron and the basic steel, and make corresponding marks on the transformer base. Generally, there should be no more than 3 gaskets, and the gaskets should not be exposed outside the base.

5.6.3 Yi amfani da alƙalami mai alama don alamar daidai matsayi na gyara rami na tushe, cire transfoma, yi amfani da rawar jirgin sama don haƙa ramuka 11 a wurin da aka yi alama, kuma yi amfani da famfo M12 don matsa ramin. a wuri a nan, kuma bayan daidaitawa, yi amfani da M12X40 plating Zinc bolts ana ɗaure su bayan wucewa ta cikin murabba’in murabba’in 12.

5.6.4 Lokacin da aka shigar da na’urar a cikin murfin karewa, da farko gyara murfin kariya bisa ga hanyar farantin tsaye, sannan yi amfani da sandar igiya don ɗaga na’urorin shigarwa na transfoma, da daidaita al’amuran babba da ƙananan gefe (idan akwai. ba zane ba ne, ya dace da ƙananan bus ɗin gefen wutan lantarki da madaidaicin layin da ke shigowa) Docking ɗin busbar na ciki zai yi nasara), saita damuwa a gaban ƙofar murfin karewa, mafi girman matakin damuwa yana juyewa tare da gefen Hanya ta ciki na murfin kariyar, tura shi cikin hanyar taransifoma, daidaita tsakiyar ƙarfin na’urar ta yadda zai yi daidai da tsakiyar murfin kariyar, sannan a danne gunkin tare da madaidaicin Haɗawa da waƙar don yin birki na nadi. dogara.

5.6.5 Aika mita zuwa dakin gyaran mita don dubawa, kuma gyara shi zuwa wurin da aka keɓe akan jikin na’ura bayan cin nasarar gwajin. Shigarwa yana da matakin da ƙarfi.

5.6.6 Abubuwan baƙin ƙarfe na babban harsashi na nau’in mai canza launin busassun jiki da madaidaicin madaidaicin ƙarfe an yi su ne da wayoyi masu mahimmanci na jan ƙarfe tare da ɓangaren giciye na 1x50mm2 ko fiye. Bayan an danna hancin tagulla na gwangwani a ƙarshen biyun, sai a murƙushe su zuwa ga lebur baƙin ƙarfe, kuma an lulluɓe gidajen da man shafawa na lantarki. Ya kamata a haɗa wurin tsaka-tsakin na’urar busassun busassun zuwa babban hanyar sadarwa ta ƙasa bisa ga buƙatun ƙira bayan wucewa ta hanyar sifili na yanzu.

5.6.7 Yi amfani da galvanized fasteners, sassa na sassa ya kamata a ɗaure, kuma tsayin daka na hakora ya kamata ya zama maɓalli 3 zuwa 5.

5.6.8 Yi gwajin bisa ga ƙayyadaddun gwajin mika wutar lantarki.

5.6.9 Bayan na’urar ta atomatik a wurin, kar a gyara ta ta hanyar waldawa, kuma a haɗa tare bayan farantin ƙarancin wutar lantarki a wurin. Bayan na’urar ta atomatik tana cikin wurin, shigar da shinge daidai daidai da alamomin.

6. Quality technical requirements

6.1 Bayan an shigar da ƙarfe na tushe na tashar tushe, samansa ya kamata ya zama 10mm sama da ƙasa mai laushi, kuma a gwada rashin daidaituwa da matakin tushe. Cikakken tsayin daka bai wuce 5mm ba.

6.2 Lokacin da aka shigar da sassan, kuskuren matakin na saman bangarori biyu na kusa bai wuce 1 mm ba, kuma saman sassan da aka tsara ba shi da ƙasa da 5 mm. Kuskuren tsaye bai kamata ya wuce 1.5/1000H na tsayinsa ba (H shine tsayin diski). Rashin daidaituwa na faifan da aka shirya a jere yana tsakanin 5 mm, kuma haɗin gwiwa tsakanin fayafai bai wuce 2 mm ba.

6.3 Kullun, kwayoyi da washers da aka yi amfani da su don haɗawa da gyara panel za su zama sassan galvanized, fenti na panel ɗin zai kasance daidai, saman panel zai kasance daidai, kuma tsarin zai kasance mai kyau.

6.4 Haɗin mashaya bas ya kamata ya zama mai kyau, kuma goyon bayan insulating da sassan shigarwa ya kamata su kasance masu ƙarfi da aminci.

6.5 Nisa tsakanin na biyu electrified jiki da lif zuwa ƙasa ba kasa da 4 mm, da kuma surface yayyo nisa ba kasa da 6 mm.

6.6 1000V megohmmeter don duba rufin bas, ya kamata ya fi 0.5 megohm.

6.7 Duk alamomin kayan aiki, alamomin launi na zamani, da alamun sunaye yakamata su kasance a sarari kuma ba su da sauƙi don canza launi.

6.8 Don kayan aikin da ba za a yi aiki ba nan da nan bayan shigarwa, ya kamata a dauki matakan kariya don hana ƙura da danshi.

7. Kariya ga aminci gini

7.1 Ya kamata a duba aikin rufe kayan aikin lantarki kafin amfani da shi, kada a sami ɗigogi, kuma harsashi ya kamata a dogara da shi.

7.2 Kada ku sanya safar hannu yayin amfani da ma’aunin lantarki.

7.3 Ya kamata a dauki matakan kariya don jigilar tafsiri, sufuri ya kamata ya kasance a hankali don hana tasirin da ya wuce kima, kuma crane ya kamata ya yi amfani da crane na hydraulic tare da kyakkyawan aiki.

7.4 Ya kamata a sami isassun haske a wurin aiki, kuma a rataye alamun gargaɗi, kuma a samar da wasu adadin na’urorin kashe gobara.

7.5 Ma’aikatan ginin da ke shiga wurin ginin dole ne su sanya ƙwararrun tufafin kariya na aiki da kwalkwali na tsaro daidai. An haramta sosai shiga wurin ginin bayan an sha. Bayan aikin yau da kullun, yakamata a kammala aikin, kayan ya zama mai tsabta, kuma wurin ya zama mai tsabta.

7.6 Ya kamata a ba da kulawa ta musamman yayin aikin gine-gine gabaɗaya, kuma kada a lalata darar gubar da sauran kayan haɗi.

7.7 Tsara ma’aikatan gine-gine don yin nazarin matakan da ƙayyadaddun yarda da gine-gine kafin ginin, kuma an haramta ayyukan ba bisa ƙa’ida ba.

7.8 Kafin aikin gwajin rayuwa na mai canzawa, yakamata a bincika da’irar sakandare don tabbatar da daidaiton da’irar sakandare.

7.9 Kafin shigar da majalisar ministocin, an kammala aikin farar hula na cikin gida don saduwa da buƙatun da ake buƙata na ruwan sama, rashin ƙarfi, lalata, da ƙura. Idan ya cancanta, ɗauki matakan gina murfin don hana lalacewa ga majalisar zartarwa.

7.10 During the transportation of the panel, it should be commanded by professional lifting personnel.

7.11 After unpacking the cabinet, pay attention to clean it in time to prevent the passage from being blocked or the nails from getting stuck.

7.12 Lokacin da kwamitin ya fara aiki, ya kamata ma’aikata su isa, kuma a haɗa umarnin don hana rauni daga faɗuwa, da hana murkushe raunuka a kunkuntar wurare.

7.13 Lokacin motsi panel, ya kamata a kula don hana lalacewa ga abubuwan da aka gyara da fenti akan panel.

7.14 Lokacin da aka yi wa kasan kwanon rufi, kada ku sanya hannuwanku cikin gindin kaskon. Lokacin da aka shigar da kwanon rufin gefe ɗaya, ya kamata ku hana hannayenku matsi yayin jingina da kwanon rufi.

7.15 Lokacin da aka gyara panel, kula da shingen katako lokacin da aka buga panel tare da guduma na hannu.

7.16 Bayan an shigar da majalisar ministocin, a kulle ƙofar panel ɗin cikin lokaci, kuma a rufe shi da zanen filastik idan ba za a yi ginin a cikin ɗan gajeren lokaci ba don hana gurɓataccen gurɓataccen abu.

7.17 Bayan an kafa ma’aikatun, ya kamata a ƙarfafa aikin aminci da tsaro. An haramtawa ma’aikatan da ba ma’aikata ba su shiga da fita daga dakin rarraba wutar lantarki, kuma ma’aikatan su rike takardar shaida don yin aiki.

7.18 Necessary fire extinguishers should be equipped in the power distribution room.

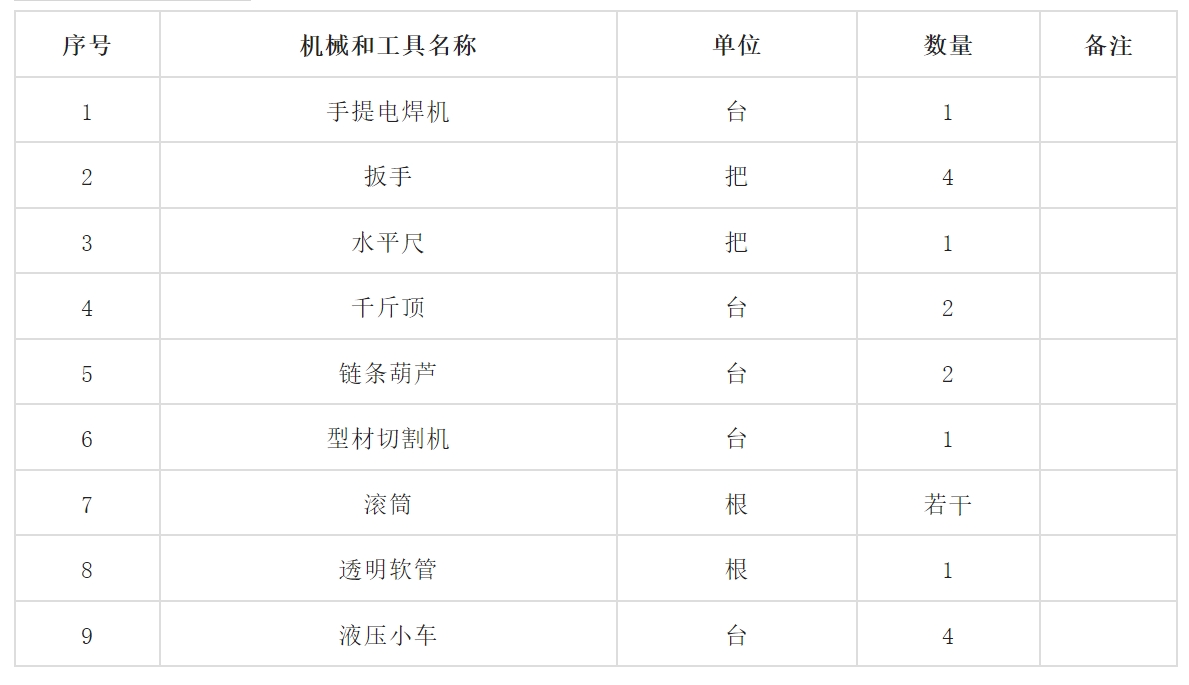

8. Babban kayan aiki