- 06

- Jan

10 kV 11 kV Tilmaamaha Rakibaadda Qalalan Nooca Qalalan, SPL-Electric

1. Ujeeddada isu-ururinta

Hagaha shaqada waxaa lagu dabaqayaa rakibaadda iyo tijaabada tooska ah ee transformers-ka nooca qalalan ee dhismaha qolka qaybinta tamarta 10kV.

2. Preparation basis

2.1 “Heerka Kormeerka Tayada iyo Qiimaynta Dhismaha Awoodda Kulaylka” ee rakibaadda korantada;

2.2 SCB10 series dry-type transformer product instruction manual;

2.3 “Safety Work Rules for Electric Power Construction”;

2.4 Sawirada naqshadaynta dhismaha ee mashruucan (mugga korantada);

2.5 “Qeexitaannada Farsamada ee Dhismaha iyo Oggolaanshaha Dhismaha Korontada”

3. nuxurka dhismaha iyo shaxda socodka hawlgalka

Low-voltage desulfurization transformer inspection, drying, body installation and transformer accessories installation, live test run.

sawir

4. Construction conditions

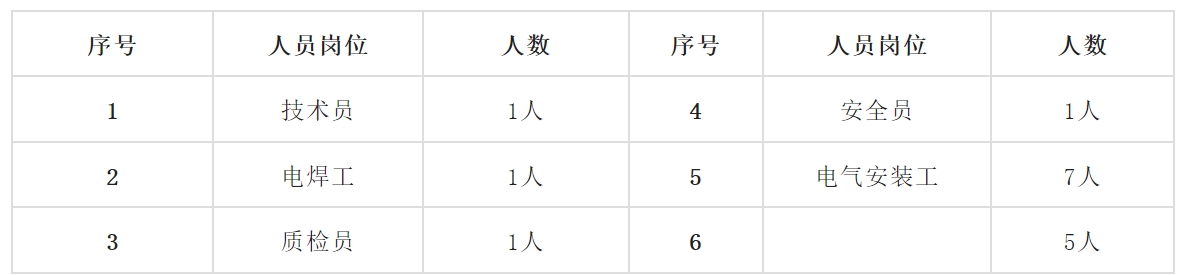

4.1 Staffing:

4.2 Conditions to be met

4.2.1 Hawshii madaniga ahayd waa la dhameeyay, goobtii waa la nadiifiyay, korkii dhulkana waxaa lagu calaamadeeyay gidaarka.

4.2.2 Tilmaamaha shaqada waa la soo ururiyey oo la ansixiyay.

4.2.3 The technicians organize the construction personnel to be familiar with the construction drawings and technical data, and make a technical disclosure, and the safety disclosure has been completed.

4.2.4 Transformer-ka ayaa la geeyey goobta.

4.2.5 Samee kormeerka baakadka iyo aqbalaadda si wadajir ah waaxyaha ay khusayso, oo samee diiwaannada.

5. Hababka iyo hababka dhismaha

5.1 Habka dhismaha:

Diyaarinta dhismaha aasaaska kanaalka wax soo saarka birta iyo rakibida Transformer Transport secondary Transformer soo dejinta kormeerka Transformer meel ku rakibida buundada baska Isku xirka baska Kormeerida taransfoorayaasha ka dib rakibidda.

5.2 Habka dhismaha

5.2.1 Soo saarista birta qaybta aasaasiga ah.

5.2.2 U hel # 8 birta kanaalka oo ah qaybta aasaasiga ah ee birta sida ku cad qeexitaanka naqshadeynta.

5.2.3 Ku rid birta kanaalka dushiisa sagxada toosan oo isticmaal dubbe si aad u toosiso. Kormeerka ka dib, sinnaanta iyo toosnaanta mitirku waxay ka yar yihiin 1.5mm.

5.2.4 Isticmaal miinshaar aan ilig lahayn si aad u gooyso alaabta iyadoo loo eegayo cabbirka naqshadaynta, oo isticmaal Furimaha Dagaalka ama feyl si aad u nadiifiso burooyinka ku yaal cidhifka miinshaarta si ay u siman yihiin.

5.2.5 Ururi jir birta profiled, isticmaal cabirka cajalad bir ah si aad u ogaato qaladka diagonal ee jir birta profiled aan ka yarayn 5mm, isticmaal heer si loo ogaado toosnaanta iyo sinnaan la’aanta birta profiled (aan ka badnayn 1.5mm per mitir, oo aan ka badnayn 5mm dhererka guud). Ka dib marka ay asal ahaan u qalmaan, waa la isugeynayaa, dib ayaa loo baarayaa, oo si adag ayaa loo alxanayaa ka dib marka ay gudbaan.

5.2.6 Isticmaal burush bir ah si aad miridhku uga saarto qaybta birta,kadibna mari lakabka rinjiga rasaasta cas si aad iskaga ilaaliso ka dib marka aad muujiso dhalaalka macdan ah,kadibna mari rinji dhamaystiran oo la mid ah ama la mid ah midabka qalabka.

5.3 Qaybta aasaasiga ah ee rakibidda birta

5.3.1 Contact the pre-embedded parts of the civil engineering cleaning department, and mark the final indoor floor elevation at the same time, and install the basic steel according to the transformer layout drawing issued by the design institute.

5.3.2 Iyadoo xariiqda dhexe ee dhismaha ay tahay xariiqda isbarbar-dhigga, hel khadka datum ee rakibaadda birta saldhigga ah (khaladku kama badna 5mm), qaado heerka sare ee dabaqa gudaha ee ugu dambeeya sida lagu calaamadeeyay injineernimada madaniga ah oo lagu daray 5mm sida diyaaradda sare datum ee birta aasaasiga ah, oo isticmaal heerka ruuxa ama U-qaabeeya Kadib habka heerka tuubada ayaa u qalma, alxanku waa adag yahay. Labada daraf ee aasaaska saxanka ee buundada busbarka ah, waa in fiiro gaar ah loo yeesho kala dheeraynta iyo isbarbardhigga birta kanaalka ee midba midka kale u dhexeeya. Ku-xidhka birta kanaalka aasaasiga ah waa inay raacdaa xeerarka.

5.3.3 Weld 8 pieces of hot-dip galvanized round steel or -40×6 hot-dip galvanized flat steel at both ends of the foundation, and connect with the main grounding grid. Twice the width; small openable doors equipped with electrical appliances shall be reliably grounded with bare copper flexible wires and grounded metal frames.

5.3.4 Dhammaan alxanka waa in dib loo rinjiyeeyaa ka dib marka laga saaro dahaarka.

5.4 Kormeeraha furista baakadaha

5.4.1 Marka la furayo sanduuqa kormeerka, shaqaalaha ay khusayso waa inay joogaan.

5.4.2 Marka hore hubi in baakadu ay dhammaatay oo aanay waxyeelo gaarin, fur sanduuqa oo sax oo tiri. Tilmaamaha, moodooyinka, iyo tirada transformers iyo panels-ka hooseeya waa inay buuxiyaan shuruudaha naqshadeynta. Agabka iyo agabka dheeriga ah waa inay ahaadaan kuwo dhamaystiran. Diiwaanada waa in la hayaa marka la furayo baakadaha, dhibaatooyinka tayada waa in kor loo qaadaa wakhtiga, iyo in la sameeyo diiwaanka baadhista baakadaha.

5.5 Gaadiidka sare ee Transformers

5.5.1 Gaadiidka ka hor, hubi nooca iyo tirada transformerka.

5.5.2 Transformer-ka waxaa lagu qaadaa baabuur, waa in aysan jirin saameyn halis ah iyo gariir inta lagu jiro gaadiidka, waana in si adag loo hagaajiyaa inta lagu jiro gaadiidka si loo hubiyo badbaadada.

5.5.3 Habka gaadiidka, shaqaale gaar ah waa in la kormeero si looga hortago leexinta.

5.5.4 Marka transformer-ka la soo dejiyo, waa in si toos ah looga dejiyaa baararka roller-ga ee horay loo dhigay. Jihada transformer-ka waa in la dhigaa iyadoo la tixgalinayo jihada loo rakibayo, iyo in Transformer-ka laga ilaaliyo in uu simbiriirixdo marka la dhigayo transformerka.

5.5.5 Marka qolofka transformer-ka nooca engegan la kala furfuri karo, qolofka waa in marka hore la kala furfuraa. Marka la burburinayo, waa in la calaamadeeyaa si looga fogaado rakibid khaldan. Marka la burburinayo, muraayadda daaqada ee indho-indheynta waa in laga ilaaliyaa inay waxyeello gaarto.

5.5.6 Marka transformer-ka la jiido, waa in la qaado tillaabooyin ka hortag ah, sida dhigista hargaha caagga ah, si looga hortago waxyeellada dhulka. Waa in laga taxadaraa in la taabto dabaylaha dabaylaha ah marka la soo dhaaminaayo.

5.5.7 The force during dragging should be uniform, consistent and coordinated, and the dragging should be slow to prevent tilting.

5.5.8 Dhismuhu waa in lagu fuliyaa amar midaysan, ilaalinta amniga, lagana ilaaliyo in gacmaha iyo cagaha lagu burburiyo biraha duuban.

5.6 Installation of dry-type transformer

5.6.1 Ka saar sanduuqa baakad ee transformer-ka nooca engegan, ku laad bar-rogadka, oo si tartiib ah ugu riix dhinaca dhinaca aasaaska birta kanaalka. Haddii loo baahdo, waxaa lagu jiidi karaa kor-u-qaadka xirmada qufulka ee ku yaal 1/3 hoose ee beddelka.

5.6.2 Marka transformer-ka nooca engegan uu si toos ah ugu dhejiyo qaybta birta, isticmaal tiir saddex-lugood leh iyo kor u qaad si aad kor ugu qaaddo transformer-ga, isticmaal heerka ruuxa, xariiq tubbo, iyo taliye bir ah si aad u cabbirto leexashada. booska, oo isticmaal habka suufka si aad u yarayso leexashada ilaa xadka ugu fiican. Isticmaal alxanka koronto inta u dhaxaysa go’yaasha birta khafiifka ah iyo inta u dhaxaysa birta dhuuban iyo birta aasaasiga ah, oo samee calaamado u dhigma saldhigga beddelka. Guud ahaan, waa in aysan jirin wax ka badan 3 gaasaska, iyo gaasaska waa in aan la soo bandhigin meel ka baxsan saldhigga.

5.6.3 Isticmaal qalinka calaamadaynta si aad u calaamadiso booska u dhigma ee daloolka hagaajinta ee saldhigga, ka saar transformerka, isticmaal daloolin diyaarad si aad u qoddo 11 godad meesha calaamadeysan, isticmaal tuubada M12 si aad u taabato daloolka, transformerku waa Meesha halkan ku taal, iyo isku toosinta ka dib, isticmaal boolal-jilicsan M12X40 oo Zinc ah ayaa la xidhaa ka dib marka la dhex maro 12 weel oo labajibbaaran.

5.6.4 When the transformer is installed in the protective cover, first fix the protective cover according to the vertical plate method, then use the tripod pole to lift the transformer installation rollers, and adjust the direction of the high and low sides (if there is no design, it is convenient for the low-voltage side busbar and incoming line cabinet) Inner busbar docking shall prevail), set traction stress in front of the protective cover door, the highest point of the stress is flush with the edge of the inner track of the protective cover, push it into the transformer track, adjust the center of gravity of the transformer so that it coincides with the center of the protective cover, and clamp the bolt with a stopper Connected to the track to make the roller brake reliably.

5.6.5 U dir mitirka qolka cabbiraadda mitirka si loo eego, oo ku hagaaji meesha loogu talagalay ee jirka beddelka ka dib markaad gudubto imtixaanka. Rakibadu waa heer iyo adag.

5.6.6 Qaybaha birta ee qolofka sare ee nooca qalalan ee jidh-bedelka iyo barta gundhigga ee xudunta birta waxay ka samaysan yihiin fiilooyin badan oo naxaas ah oo leh qayb iskutallaab ah oo ah 1x50mm2 ama ka badan. Ka dib marka la cadaadiyo sanka naxaasta ah ee qasacadaysan ee labada daraf, waxa lagu maroojiyaa birta fidsan, iyo kala-goysyada waxaa lagu dahaadhay dufan isku dhafan oo koronto ah. Barta dhexdhexaadka ah ee qalabka qalalan ee nooca qalalan waa in lagu xiraa shabakadda ugu weyn ee dhulka iyadoo loo eegayo shuruudaha naqshadeynta ka dib marka la dhex maro isbeddelka hadda jira ee eber.

5.6.7 Isticmaal xirmooyinka galvanized, qaybaha dabacsan waa in la dhejiyaa, dhererka daboolka ee ilkahu waa inay ahaadaan 3 ilaa 5 badhamada.

5.6.8 Samee tijaabada sida ku cad qeexitaanka tijaabada wareejinta korantada.

5.6.9 Ka dib markii taransfooriyaha uu ku jiro, ha ku hagaajin alxanka, oo wada alxan ka dib marka saxanka hooseeya ee meesha uu yaal. Ka dib markii qalabku meesha yaal, ku dheji meesha si sax ah sida ku cad calaamadaha.

6. Shuruudaha farsamada tayada

6.1 Ka dib marka la rakibo birta kanaalka aasaasiga ah, dusheeda waa inay ahaataa 10mm ka sarraysa dhulka la jeexjeexay, oo aan toosnayn iyo heerka aasaasiga ah waa in la tijaabiyaa. Dhererka buuxa ee weecintu waa in ka yar 5mm.

6.2 Marka saqafyada la rakibo, khaladka heerka sare ee labada dhinac ee ku xiga waa in ka yar 1 mm, dusha sare ee saqafka ayaa ka yar 5 mm. Khaladka toosan waa inuusan ka weynaan 1.5/1000H ee dhererkiisa (H waa dhererka saxanka). Sinnaan la’aanta saxannada iskuxiran ee loo habeeyay waxay u dhexaysaa 5 mm, isku-dhafka u dhexeeya saxanadaha ayaa ka yar 2 mm.

6.3 Dhalooyinka, looska iyo dhaqdhaqaayada loo isticmaalo isku xirka iyo hagaajinta guddiga waa inay ahaadaan qaybo galvanized, rinjiga guddigu waa inuu ahaadaa mid sax ah, dusha sare ee guddiga waa inuu ahaadaa mid joogto ah, habayntuna waa inay ahaato mid nadiif ah.

6.4 Isku xirka baska baska waa inuu ahaadaa mid wanaagsan, taageerada dahaarka iyo qaybaha rakibida waa inay ahaadaan kuwo adag oo la isku halayn karo.

6.5 Masaafada u dhaxaysa jidhka labaad ee korontada ku shaqeeya iyo wiishka dhulka waa mid aan ka yarayn 4 mm, masaafada dusha sare ee qulqulka ayaa ah mid aan ka yarayn 6 mm.

6.6 1000V megohmmeter si loo hubiyo dahaadhka baska, waa inuu ka weynaadaa 0.5 megohm.

6.7 Dhammaan calamadaha qalabka, calamadaha midabka wejiga, iyo calamadaha wareegga wareegga waa inay ahaadaan kuwo cad oo aan si fudud loo beddelin.

6.8 For the equipment that will not be put into operation immediately after installation, protective measures should be taken to prevent dust and moisture.

7. Ka taxadarida dhismaha nabdoon

7.1 Waxqabadka dahaarka ee qalabka korantada waa in la fiiriyaa ka hor inta aan la isticmaalin, waa in aysan jirin wax qulqulaya, qolofkuna waa in si kalsooni leh loo dejiyaa.

7.2 Ha xidhin galoofyada marka aad isticmaalayso laylisyada korontada.

7.3 Tallaabooyin ilaalin ah waa in la qaadaa si loo daabulo transformer-ka, gaadiidku waa inuu gaabiyaa si looga hortago saamaynta xad dhaafka ah, wiishkuna waa inuu isticmaalo wiishashka hadhka leh ee waxqabadka wanaagsan leh.

7.4 Waa in goobta shaqada laga helaa nalal ku filan, calaamada digniinta waa in la suraa, tiro cayiman oo dab-damis ahna waa in la qalabeeyaa.

7.5 Shaqaalaha dhismaha ee galaya goobta dhismaha waa in ay si sax ah u xidhaan dharka ilaalinta shaqada iyo koofiyada badbaadada. Waa mamnuuc in la galo goobta dhismaha ka dib markaad cabto. Ka dib dhismaha maalinlaha ah, shaqada waa in la dhammeeyaa, alaabtu waa inay nadiif ahaadaan, goobtana waa inay nadiif ahaadaan.

7.6 Waa in fiiro gaar ah la siiyaa inta lagu jiro habka dhismaha oo dhan, iyo kaynta rasaasta iyo agabka kale waa in aan la dhaawacmin.

7.7 Abaabulaan shaqaalaha dhismaha si ay u daraaseeyaan cabbirada iyo aqbalitaanka dhismaha ka hor dhismaha ka hor, iyo hawlgallada sharci darrada ah si adag waa mamnuuc.

7.8 Ka hor inta aan la bilaabin hawlgalka tijaabada tooska ah ee beddelka, wareegga labaad waa in la hubiyaa si loo hubiyo saxnaanta wareegga sare.

7.9 Ka hor inta aan la rakibin golaha wasiirada, shaqada madaniga ah ee gudaha ayaa la dhammeeyaa si loo buuxiyo shuruudaha roobka, qoyaanka-celinta, ka hortagga daxalka, iyo boodhka. Haddii loo baahdo, qaado tillaabooyin si aad u dhisto dabool si aad uga hortagto burbur soo gaara golaha wasiirada.

7.10 Inta lagu jiro gaadiidka guddiga, waa in ay amar ku bixiyaan shaqaale xirfad leh.

7.11 Ka dib markaad furto golaha wasiirada, fiiro gaar ah u yeelo si aad u nadiifisid wakhtiga si aad uga ilaaliso marinka in la xiro ama in ciddiyaha ay ku dhegaan.

7.12 Marka guddiga la soo bandhigo, waa in cududku ku filan yahay, taliskuna waa in la mideeyaa si looga hortago dhaawac ka soo dhacay, lagana ilaaliyo dhaawacyada burburka ee meelaha cidhiidhiga ah.

7.13 Marka la guurayo guddiga, waa in taxaddar la sameeyaa si looga hortago waxyeellada qaybaha iyo rinjiyeynta guddiga.

7.14 Markaad suufka hoose ee digsiga, ha gelin gacmahaaga gunta digsiga. Marka digsiyada hal-dhinac ah lagu rakibo dhinac dhinac, waa inaad ka ilaalisaa gacmahaaga in la tuujiyo markaad ku tiirsato digsiga.

7.15 Marka guddiga la hagaajiyo, fiiro gaar ah u yeelo xannibaadda alwaax markaad ku dhufanayso dubbe gacanta.

7.16 Ka dib marka la rakibo golaha golaha, albaabka guddida xidh, oo ku dabool maro caag ah haddii aan dhismo lagu samayn muddo gaaban gudaheed si looga hortago wasakhda labaad.

7.17 Ka dib marka golaha wasiirada la dhiso, waa in la xoojiyaa shaqada amniga iyo amniga. Waxaa si adag loo mamnuucay in shaqaalaha aan shaqaalaha ahayn ay galaan kana baxaan qolka korontada, shaqaaluhuna waa inay haystaan shahaado ay ku shaqeeyaan.

7.18 Dab-damiska daruuriga ah waa in lagu qalabeeyaa qolka korontada.

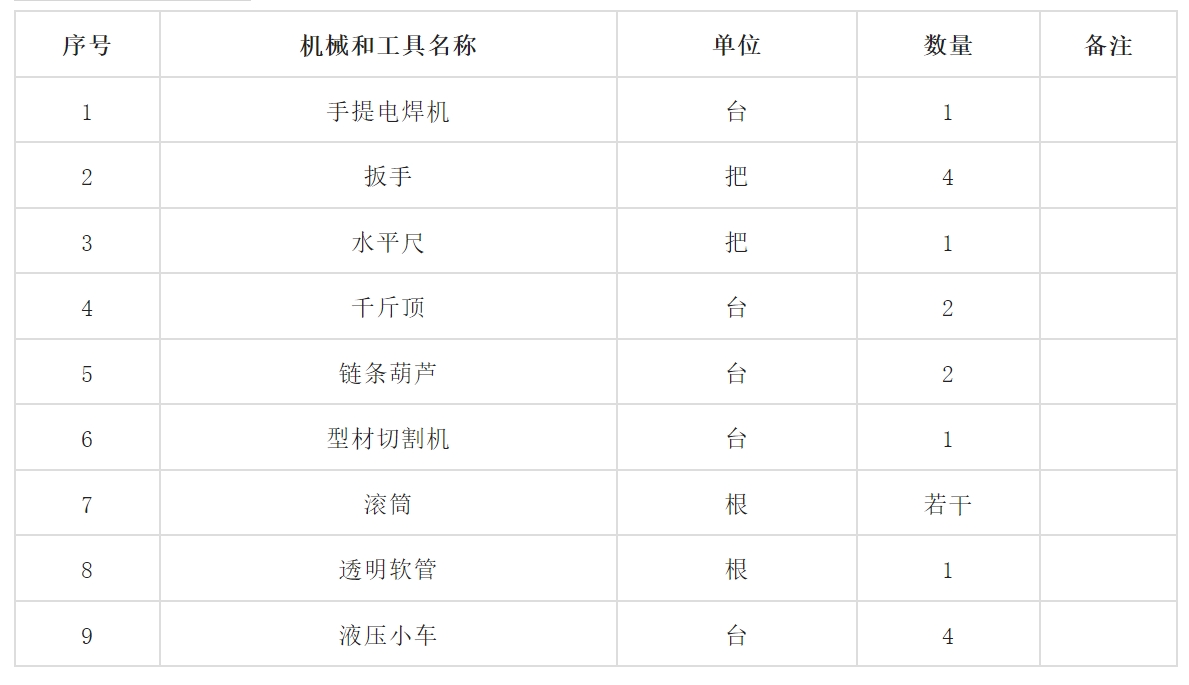

8. Qalabka ugu muhiimsan