- 06

- Jan

10 kV 11 kV quruq transformatorni o’rnatish bo’yicha yo’riqnoma, SPL-Elektr

1. Purpose of compilation

Ushbu ish qo’llanma 10 kV kuchlanishli elektr taqsimlash xonasini qurishda quruq turdagi transformatorlarni o’rnatish va jonli sinovdan o’tkazish uchun qo’llaniladi.

2. Tayyorgarlik asosi

2.1 “Standards for Quality Inspection and Evaluation of Thermal Power Construction” for electrical installations;

2.2 SCB10 seriyali quruq turdagi transformator mahsuloti bo’yicha qo’llanma;

2.3 “Elektr energiyasini qurishda xavfsizlik qoidalari”;

2.4 Construction design drawings of this project (electric volume);

2.5 “Technical Specifications for Construction and Acceptance of Electric Power Construction”

3. Qurilish mazmuni va ishlash sxemasi

Past kuchlanishli desulfurizatsiya transformatorini tekshirish, quritish, korpusni o’rnatish va transformator aksessuarlarini o’rnatish, jonli sinovdan o’tkazish.

surat

4. Qurilish shartlari

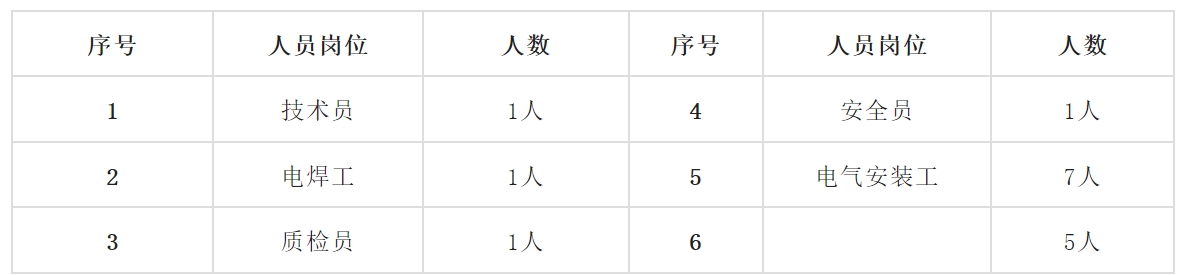

4.1 Staffing:

4.2 Conditions to be met

4.2.1 The civil work has been completed, the site is cleaned up, and the ground elevation is marked on the wall.

4.2.2 Ish ko’rsatmalari tuzilgan va tasdiqlangan.

4.2.3 Mutaxassislar qurilish xodimlarini qurilish chizmalari va texnik ma’lumotlar bilan tanishishlarini tashkil qiladi va texnik ma’lumot beradi va xavfsizlikni oshkor qilish tugallanadi.

4.2.4 The transformer has been delivered to the site.

4.2.5 Carry out unpacking inspection and acceptance together with relevant departments, and make records.

5. Construction procedures and methods

5.1 Construction procedure:

Construction preparation Foundation channel steel production and installation Transformer secondary transportation Transformer unpacking inspection Transformer in place Bus bridge installation Bus connection Inspection of transformer after installation.

5.2 Construction method

5.2.1 Production of basic section steel.

5.2.2 Dizayn spetsifikatsiyasiga muvofiq №8 kanalli po’latni asosiy qism po’lat sifatida oling.

5.2.3 Kanal po’latini gorizontal platformaga qo’ying va uni to’g’rilash uchun balyozdan foydalaning. Tekshiruvdan so’ng, har bir metr uchun notekislik va tekislik 1.5 mm dan kam.

5.2.4 Materialni dizayn o’lchamiga muvofiq kesish uchun tishsiz arradan foydalaning va silliq bo’lishi uchun arra chetidagi burmalarni tozalash uchun maydalagich yoki fayldan foydalaning.

5.2.5 Profillangan po’lat ramkani yig’ing, profilli po’latdan yasalgan ramkaning diagonal xatosini aniqlash uchun po’lat lenta o’lchovidan foydalaning 5 mm dan kam bo’lmagan, profilli po’latning tekisligi va notekisligini aniqlash uchun darajadan foydalaning (har biriga 1.5 mm dan oshmasligi kerak). metr va umumiy uzunligi 5 mm dan oshmasligi kerak). Ular asosan malakali bo’lgandan so’ng, ular bir-biriga payvandlanadi, yana qayta tekshiriladi va o’tgandan keyin mustahkam payvandlanadi.

5.2.6 Temir cho’tka yordamida po’lat po’latdan zangni olib tashlang, so’ngra metall porlashi paydo bo’lgandan keyin korroziyaga qarshi qizil qo’rg’oshinli bo’yoq qatlamini qo’llang, so’ngra metallning rangi bilan bir xil yoki o’xshash bo’yoqni qo’llang. uskunalar.

5.3 Asosiy qism po’latni o’rnatish

5.3.1 Qurilish inshootlarini tozalash bo’limining oldindan o’rnatilgan qismlari bilan bog’laning va bir vaqtning o’zida oxirgi ichki qavat balandligini belgilang va loyiha instituti tomonidan chiqarilgan transformator sxemasi chizmasiga muvofiq asosiy po’latni o’rnating.

5.3.2 Binoning markaziy chizig’i parallel chiziq sifatida, asosiy po’latni o’rnatish chizig’ini toping (xato 5 mm dan oshmaydi), qurilish muhandisligi tomonidan belgilangan ichki qavatning oxirgi balandligini va yuqori tekislik sifatida 5 mm ni oling. asosiy po’latning ma’lumotlari, va suv sathidan yoki U-shaklidagi foydalaning Quvur darajasi usuli malakali bo’lgandan so’ng, payvandlash mustahkam bo’ladi. Shina ko’prigi bo’lgan plastinka poydevorining har ikki uchida kanal po’latining bir-birining orasidagi masofa va parallelligiga e’tibor qaratish lozim. Poydevor kanali po’latini joylashtirish qoidalarga muvofiq bo’lishi kerak.

5.3.3 Weld 8 pieces of hot-dip galvanized round steel or -40×6 hot-dip galvanized flat steel at both ends of the foundation, and connect with the main grounding grid. Twice the width; small openable doors equipped with electrical appliances shall be reliably grounded with bare copper flexible wires and grounded metal frames.

5.3.4 Barcha payvand choklari qoplamani olib tashlagach, qayta bo’yalgan bo’lishi kerak.

5.4 Transformer unpacking inspection

5.4.1 When opening the box for inspection, relevant personnel should be present.

5.4.2 Avval qadoqning to’liq va buzilmaganligini tekshiring, qutini oching va tekshiring va hisoblang. Transformatorlar va past kuchlanishli panellarning texnik xususiyatlari, modellari va miqdori dizayn talablariga javob berishi kerak. Aksessuarlar va ehtiyot qismlar to’liq bo’lishi kerak. Paketni ochish tekshiruvi uchun yozuvlar saqlanishi kerak, sifat bilan bog’liq muammolar o’z vaqtida ko’tarilishi kerak va qadoqdan ochish tekshiruvi uchun yozuvlar kiritilishi kerak.

5.5 Transformatorlarni ikkilamchi tashish

5.5.1 Tashishdan oldin transformatorning turi va miqdorini tekshiring.

5.5.2 Transformator avtomobil bilan tashiladi, tashish paytida jiddiy ta’sir va tebranish bo’lmasligi kerak va xavfsizlikni ta’minlash uchun tashish paytida mahkam o’rnatilishi kerak.

5.5.3 In the process of transportation, special personnel should be supervised to prevent tilting.

5.5.4 When the transformer is unloaded, it should be unloaded directly on the pre-placed roller bars. The direction of the transformer should be placed in consideration of the installation direction, and the transformer should be prevented from sliding when placing the transformer.

5.5.5 When the shell of the dry-type transformer can be disassembled, the shell should be dismantled first. When dismantling, it should be marked to avoid wrong installation. When dismantling, the observation window glass should be prevented from being damaged.

5.5.6 Transformator tortilganda, erga shikast etkazmaslik uchun rezina terilarni yotqizish kabi himoya choralarini ko’rish kerak. Tashish paytida izolyatsiyalangan o’rashlarga tegmaslik uchun ehtiyot bo’lish kerak.

5.5.7 The force during dragging should be uniform, consistent and coordinated, and the dragging should be slow to prevent tilting.

5.5.8 Construction should be carried out under unified command, pay attention to safety, and prevent hands and feet from being crushed by rolling bars.

5.6 Quruq transformatorni o’rnatish

5.6.1 Remove the packing box of the dry-type transformer, hang it on the roller bar, and slowly push it to the side of the channel steel foundation. If necessary, it can be pulled by a hoist on the lock frame at the lower 1/3 of the transformer.

5.6.2 When the dry-type transformer is directly fixed on the section steel, use a three-legged pole and a hoist to lift the transformer into place, use a spirit level, a plumb line, and a steel ruler to measure the deviation in position, and use the method of padding to reduce the deviation to within the excellent range. Use electric welding between the thin iron sheets and between the thin iron and the basic steel, and make corresponding marks on the transformer base. Generally, there should be no more than 3 gaskets, and the gaskets should not be exposed outside the base.

5.6.3 Poydevorning mahkamlash teshigining mos keladigan o’rnini belgilash uchun markirovka ruchkasidan foydalaning, transformatorni olib tashlang, belgilangan joyda 11 teshikni burg’ulash uchun samolyot matkasidan foydalaning va teshikka tegish uchun M12 krandan foydalaning, transformator bu erda o’rnida va tekislashdan so’ng, M12X40 qoplamasidan foydalaning Rux murvatlari 12 kvadrat eğimli rondeladan o’tgandan keyin mahkamlanadi.

5.6.4 Transformator himoya qopqog’iga o’rnatilganda, birinchi navbatda vertikal plastinka usuli bo’yicha himoya qopqog’ini mahkamlang, so’ngra transformatorni o’rnatish roliklarini ko’tarish uchun tripod ustunidan foydalaning va yuqori va past tomonlarning yo’nalishini sozlang (agar mavjud bo’lsa). dizayn yo’q, u past kuchlanishli yon shinalar va kiruvchi liniyalar shkafi uchun qulaydir) Shinaning ichki o’rnatilishi ustun bo’lishi kerak), himoya qopqog’i eshigi oldida tortish kuchlanishini o’rnating, kuchlanishning eng yuqori nuqtasi chekkasi bilan teng. himoya qopqog’ining ichki yo’lini transformator yo’liga surib qo’ying, transformatorning og’irlik markazini himoya qopqog’ining markaziga to’g’ri keladigan tarzda sozlang va rolikli tormozni qilish uchun murvatni tiqin bilan mahkamlang. ishonchli tarzda.

5.6.5 Send the meter to the meter calibration room for inspection, and fix it to the designated place on the transformer body after passing the test. The installation is level and firm.

5.6.6 The iron components of the upper shell of the dry-type transformer body and the grounding point of the iron core are made of multi-strand copper core wires with a cross-section of 1x50mm2 or more. After pressing tinned copper noses at both ends, they are screwed to the grounded flat iron, and the joints are coated with electric compound grease. The neutral point of the dry-type transformer should be connected to the main grounding network according to the design requirements after passing through the zero-sequence current transformer.

5.6.7 Use galvanized fasteners, the loose parts should be fastened, and the exposed length of the screw teeth should be 3 to 5 buttons.

5.6.8 Sinovni elektr uzatish sinovi spetsifikatsiyasiga muvofiq o’tkazing.

5.6.9 Transformator o’rnatilgandan so’ng, uni payvandlash yo’li bilan tuzatmang va past kuchlanishli plastinka o’rnatilgandan keyin bir-biriga payvandlang. Transformator o’rnatilgandan so’ng, korpusni belgilarga muvofiq to’g’ri o’rnating.

6. Sifat bo’yicha texnik talablar

6.1 After the foundation channel steel is installed, its top should be 10mm higher than the troweled ground, and the non-straightness and levelness of the foundation should be tested. The full length deviation is less than 5mm.

6.2 When the panels are installed, the level error of the tops of two adjacent panels is less than 1 mm, and the top of the arrayed panels is less than 5 mm. The vertical error should not be greater than 1.5/1000H of its height (H is the disk height). The unevenness of the disks arranged in a row is within 5 mm, and the joint between the disks is less than 2 mm.

6.3 The bolts, nuts and washers used to connect and fix the panel shall be galvanized parts, the paint of the panel shall be intact, the surface of the panel shall be consistent, and the arrangement shall be neat.

6.4 Avtobus panelining ulanishi yaxshi bo’lishi kerak va izolyatsiyalovchi tayanch va o’rnatish qismlari mustahkam va ishonchli bo’lishi kerak.

6.5 Ikkilamchi elektrlashtirilgan korpus va lift orasidagi masofa 4 mm dan kam emas, sirt oqish masofasi esa 6 mm dan kam emas.

6.6 1000V megohmmeter to check the bus insulation, it should be greater than 0.5 megohm.

6.7 All equipment marks, phase color marks, and circuit name marks should be clear and not easy to decolorize.

6.8 O’rnatishdan so’ng darhol ishga tushirilmaydigan uskunalar uchun chang va namlikning oldini olish uchun himoya choralarini ko’rish kerak.

7. Precautions for safe construction

7.1 Elektr asboblarining izolyatsiyalash ko’rsatkichlarini ishlatishdan oldin tekshirish kerak, hech qanday qochqin bo’lmasligi kerak va qobiq ishonchli tarzda erga ulangan bo’lishi kerak.

7.2 Elektr matkaplardan foydalanganda qo’lqop kiymang.

7.3 Transformatorni tashish uchun himoya choralarini ko’rish kerak, transport haddan tashqari ta’sirni oldini olish uchun sekin bo’lishi kerak va kran yaxshi ishlashi bilan gidravlik kranni ishlatishi kerak.

7.4 Ish joyida etarli yorug’lik bo’lishi kerak va ogohlantiruvchi belgilar osilgan bo’lishi kerak va ma’lum miqdordagi o’t o’chirish moslamalari bilan jihozlangan bo’lishi kerak.

7.5 Qurilish maydonchasiga kirayotgan qurilish xodimlari malakali mehnatni muhofaza qilish kiyimlari va xavfsizlik dubulg’alarini to’g’ri kiyishlari kerak. Ichkilikdan keyin qurilish maydonchasiga kirish qat’iyan man etiladi. Kundalik qurilishdan so’ng ish tugallanishi, materiallar toza bo’lishi va sayt toza bo’lishi kerak.

7.6 Special attention should be paid during the whole construction process, and the lead-out bushing and other accessories should not be damaged.

7.7 Qurilishdan oldin chora-tadbirlar va qurilishni qabul qilish spetsifikatsiyalarini o’rganish uchun qurilish xodimlarini tashkil qiling va noqonuniy operatsiyalar qat’iyan man etiladi.

7.8 Transformatorning jonli sinov ishlashidan oldin, ikkilamchi sxemaning to’g’riligini ta’minlash uchun ikkilamchi sxemani tekshirish kerak.

7.9 Panelli shkafni o’rnatishdan oldin, yomg’irga chidamli, namlikka chidamli, korroziyaga qarshi va changga chidamlilik talablariga javob beradigan ichki qurilish ishlari yakunlanadi. Agar kerak bo’lsa, panel shkafiga zarar etkazmaslik uchun qopqoqni qurish choralarini ko’ring.

7.10 During the transportation of the panel, it should be commanded by professional lifting personnel.

7.11 After unpacking the cabinet, pay attention to clean it in time to prevent the passage from being blocked or the nails from getting stuck.

7.12 Panel o’rnatilganda, ishchi kuchi etarli bo’lishi kerak va jarohatlarning yiqilib tushishiga yo’l qo’ymaslik va tor joylarda ezilgan jarohatlarning oldini olish uchun buyruq birlashtirilishi kerak.

7.13 Panelni ko’chirishda paneldagi qismlarga va bo’yoqlarga shikast etkazmaslik uchun ehtiyot bo’lish kerak.

7.14 Idishning pastki qismini to’ldirganda, qo’llaringizni panning pastki qismiga qo’ymang. Bir tomonlama kostryulkalar yonma-yon o’rnatilganda, panga suyanganda qo’llaringizni siqib qo’yishning oldini olishingiz kerak.

7.15 Panel o’rnatilganda, panelni qo’l bolg’asi bilan urishganda yog’och blokga e’tibor bering.

7.16 After the panel cabinet is installed, lock the panel door in time, and cover it with plastic cloth if construction will not be carried out in a short period of time to prevent secondary pollution.

7.17 Shkaflar o’rnatilgandan so’ng, xavfsizlik va xavfsizlik ishlarini kuchaytirish kerak. Xodim bo’lmagan xodimlarning elektr taqsimlash xonasiga kirishi va chiqishi qat’iyan man etiladi va xodimlar ishlash uchun sertifikatga ega bo’lishi kerak.

7.18 Elektr taqsimlash xonasida zarur o’t o’chirish moslamalari jihozlangan bo’lishi kerak.

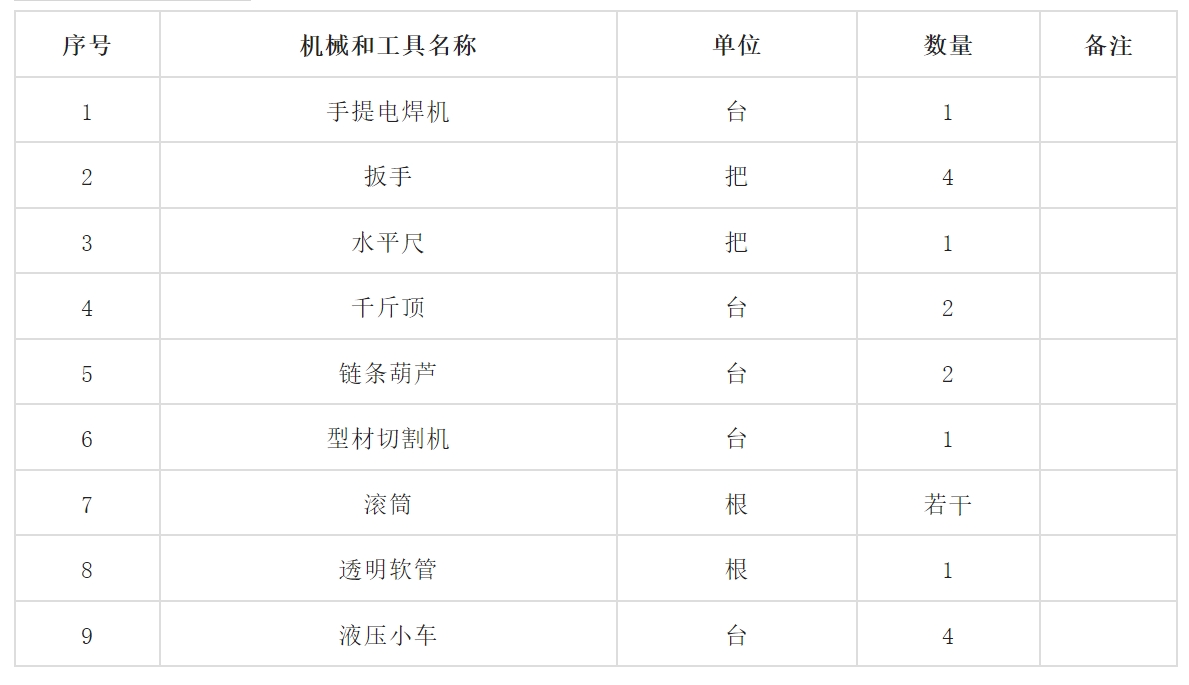

8. Main tools