- 02

- Oct

How to deal with transformer oil # Answer from a transformer manufacturer in China

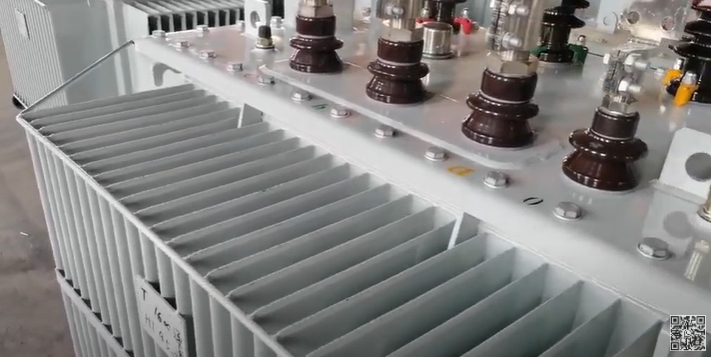

In order to improve the insulation strength, dielectric loss coefficient and other indicators of the transformer oil, the transformer oil must be treated before being injected into the oil tank to remove the water, gas and impurities in the oil. In practical application, we have carried out targeted treatment for different types of transformer oil, with good results.

1. For transformer oil generally polluted by impurities such as water and dust, plate and frame filter press can be used. After multiple cycles of filtration, it can basically meet the requirements. Its principle is to use oil filter paper to absorb water and filter impurities. Because of its simple structure and convenient handling, it is also widely used. The disadvantage is that the filtration is not complete, the removal effect of fine impurities is not good, and the cost is relatively high. When the moisture is large, the oil filter paper needs to be replaced frequently.

2. Now the vacuum oil filter is widely used, which can not only completely remove water and gas in the oil, but also effectively remove small impurities. The process flow is: transformer oil to be treated → coarse filtration → fine filtration → vacuum dehydration and degassing of heating oil → oil purification. Metal filter screen and powerful magnet are used for coarse filtration to remove 1~ μ M Trace impurities. At present, there are many kinds of fine filters, including sintered metal powder materials, metal microporous materials, ceramic filter materials and filter elements with special structures. Data from: power transmission and distribution equipment network

The transformer oil is heated, vacuumized, dehydrated and degassed. The principle is to vacuum the oil tank and spray the heated transformer oil to form oil mist, so that the gas and water in the oil can escape. The oil temperature is generally about 65 ℃ and should not be too high to avoid oil aging. This method has good dehydration and degassing effect, and is currently a commonly used method. However, if the oil is sprayed into a very fine mist, it is easy to be pumped away by the vacuum pump.

If the oil is sprayed into oil droplets with a certain diameter, the water vapor in the oil droplets will not be fully utilized due to the high interfacial tension of the oil droplets. Therefore, the diameter of the spray hole should be correctly selected, and some baffles should be set at the suction port of the oil tank to prevent the transformer oil from being pumped away by the vacuum pump.

At present, more advanced membrane dehydration and degassing methods are also used at home and abroad. Even though the oil entering the tank forms an extremely thin oil film after some degassing elements, the whole dehydration and degassing process is completed in one dehydration and degassing process. The oil film state makes it easy to remove the water and gas in the oil.

3. Treatment of contaminated transformer oil. Contaminated transformer oil (commonly known as dirty oil) refers to transformer oil polluted by colloid formed by combination of tiny impurities and oil molecules, as well as transformer oil that has been used for many years. Generally, it is the oil discharged from maintenance products (the pH value of this oil is already very low). This kind of waste oil must be treated by adsorption to improve the oil index. Silica gel (SiO2) or activated alumina (A12O3) is generally used as adsorbent. In the waste oil treatment system, in order to ensure full contact between silica gel and transformer oil and facilitate the replacement of silica gel, a number of diaphragms are set in the silica gel tank, and the silica gel is put into a small cloth bag for emergencies. Rotation, not bulk. The heated transformer oil is sent to the silicone oil tank for a certain cycle, so that it can fully play its adsorption role, and then it is injected into the clean oil tank through the oil filter. Regular monitoring shall be conducted during treatment to determine the adsorption effect. When the adsorption effect is not obvious, replace the silica gel. Generally, the amount of silica gel accounts for 3%~5% of the oil weight. The waste oil treatment system shall be separated from the new oil treatment system to avoid cross contamination. The oil tank and container filled with dirty oil must be thoroughly cleaned before normal production in the oil system.