- 10

- Sep

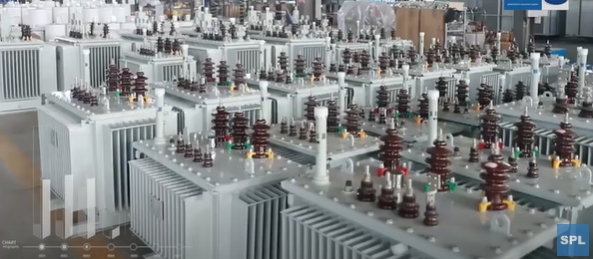

How to select the right power transformer?

Transformer selection generally must be considered comprehensively from the aspect of transformer capacity, voltage, current and environmental conditions. Among them, the selection of capacity must be based on the capacity, nature and time of use of the user’s electrical equipment to determine the required load, so as to choose the capacity of the transformer. During normal operation, the transformer power load should be about 75% to 90% of the rated capacity of the transformer.

If the actual rated load of the transformer is less than 50% during operation, the small capacity transformer should be replaced, and if it is greater than the rated capacity of the transformer, the large transformer should be replaced immediately. At the same time, when selecting a transformer, the primary winding voltage value of the transformer should be determined according to the power supply line, and the secondary winding voltage value should be selected according to the electrical equipment. to select a low-voltage three-phase four-wire power supply. It can provide power and lighting power at the same time.

When we usually choose a distribution transformer, if the capacity is too large, the phenomenon of “big horse-drawn trolley” will be formed, which not only increases the equipment investment, but also keeps the transformer in a no-load state for a long time. . , increase reactive power loss; if the capacity of the transformer is too small, the transformer will be in an overloaded state for a long time, and the transformer will burn out easily, whether it is an autotransformer or a three-phase transformer, it is the same. Therefore, selecting the right transformer capacity is one of the important steps to reduce losses and save energy in the power grid. In practical applications, we can choose the transformer capacity according

to the following simple method.

Step:

1. When we usually choose a distribution transformer, if the capacity is too large, the phenomenon of “big horse-drawn trolley” will be formed, which not only increases the equipment investment, but also keeps the transformer in no-load condition for a long time. long If the transformer capacity is too small, the transformer will be in an overloaded state for a long time, and it is easy to burn out the transformer, whether it is an autotransformer or a three-phase transformer, it is the same. Therefore, selecting the right transformer capacity is one of the important steps to reduce losses and save energy in the power grid. In practical applications, we can choose the transformer capacity according to the following simple method.

2. The principle of “small capacity, dense distribution” should be adhered to. The distribution transformer should be placed in the load center as much as possible, and the power supply radius should not exceed 0.5 kilometers. The load rate of the distribution transformer is highest between 0.5 and 0.6, and the current capacity of the transformer is called the economic capacity. However, if the load is relatively stable, the transformer capacity can be selected according to the economic capacity in terms of continuous production.

3. According to the characteristics of rural power grid users scattered, low load density, strong seasonal and intermittent strong load, etc., capacity adjustment transformer can be used. The capacity regulating transformer is a transformer that can adjust the no-load capacity according to the size of the load, suitable for use in places where seasonal changes in load are clearly visible. For substations or industrial and mining enterprises with large power loads, the main and subsidiary transformers are generally used for power supply, one (mother) is configured according to the maximum load, and the other (secondary) is selected according to the low load circumstances, which can greatly improve power distribution. Transformer utilization, reduces the no-load losses of distribution transformers. In view of the fact that some distribution transformers in rural areas are in low-load operation for a long time except for a small number of peak electrical loads in a year, for users with conditions, the mother-son transformer or transformer parallel operating power supply modes can also be used. When the load changes greatly, according to the principle of the lowest power loss, put it in a transformer with a different capacity. For special transformers that only supply power to power loads such as irrigation and drainage, the transformer capacity can generally be selected according to 1.2 times the asynchronous motor nameplate power. Generally, the motor starting current is four to seven times the rated current, and the transformer must be able to withstand this impact.The capacity of one of the largest motors starting directly should generally not exceed about 30% of the transformer capacity. It should be pointed out that special transformers for drainage and irrigation should generally not be connected to other loads, thereby stopping operation in time during non-drainage and irrigation periods and reducing electrical energy losses.